– Michelle Arnold, DVM (Ruminant Extension Veterinarian, UKVDL), Dr. Ray Smith, Livestock Forage Extension Specialist, and Krista Lea –UK Dept of Plant and Soil Sciences

Baleage or “wet wrapped hay” is simply forage of a relatively high moisture content that is baled with a round baler and then sealed in a plastic bag or wrapped in plastic, to keep oxygen out. Anaerobic bacteria (those that live without air) convert sugars in the forage to lactic acid which in turn lowers the pH and preserves the forage as silage, with full fermentation completed within 6-8 weeks. Round bale silage (“baleage”) is an alternative to baling dry hay that allows shorter curing time and saves valuable nutrients by avoiding rain damage, harvest delays, spontaneous heating and weathering if stored outdoors. Grasses, legumes and small grains can be effectively preserved by this method but only if proper techniques are followed. Forages should be cut at early maturity with high sugar content, allowed to wilt to a 40-60% moisture range, then tightly baled and quickly wrapped in plastic to undergo fermentation (“ensiling” or “pickling”), a process that should drop the pH of the feed below 4.5 where spoilage organisms will not grow. Problems arise when conditions in the bale allow growth of disease-causing organisms and potentially fatal conditions in cattle.

Why do problems occur?

- Forage cut at the wrong stage of maturity will not have enough fermentable carbohydrates for good ensiling. Coarse, stemmy and overly mature forages have less sugars available for completion of fermentation, especially once the seed head has emerged. Small grains including rye, oats, wheat, and barley have a narrow harvest window and should be cut before the boot stage.

- Lower bale density makes round bale silage more susceptible to entrapment or penetration of oxygen and increases the chance of air pockets within the bale. Tight, dense bales wrapped with plastic twine, net-wrap or untreated sisal twine are less likely to spoil.

- Baling at the incorrect moisture content is a recipe for disaster. Wet or non-wilted forages are more likely to spoil; bacteria from the Clostridia family thrive in wet environments where forage moistures are in the higher 67-70% range. Greater than 70% moisture almost guarantees Clostridial growth and spoilage. Conversely, forage that is too dry does not ferment but has greatly increased mold production.

- Baled silage is also more likely to spoil due to damage to the plastic covering, resulting in the harmful introduction of oxygen. It is important not to puncture the plastic; isolate the area from cattle, pests and vermin. Anything that claws, bites or otherwise punctures the plastic sets the feed up for spoilage.

What are the health risks to cattle?

- Botulism is a disease caused by one of the most potent toxins known to man. This toxin is produced by Clostridium botulinum, a spore-forming anaerobic Gram + rod. These spores are found everywhere in the soil and contaminate baleage during harvest, often by raking up dirt. In the absence of oxygen (as is found in wrapped hay) and a pH greater than 4.5 (poor fermentation), the spores enter a vegetative state, multiply and produce toxin. Two forms of the toxin, Types B and C, are found most frequently in KY cattle. Type B is associated with improperly fermented forage while Type C occurs from the accidental feeding of dead animals or poultry litter in the ration of cattle. Both types produce the same characteristic clinical picture in cattle of progressive muscle weakness leading to recumbency (downers) over a 2-5 day period of time, depending on the amount of toxin ingested. Signs may develop as early as 24 hours to as many as 10 days after ingesting the toxin. Death is due to paralysis of muscles of the diaphragm, dehydration, or complications from being a “downer”.

- Listeriosis or “Circling Disease” is an encephalitis caused by the bacterium Listeria monocytogenes. This organism proliferates in soil, feces and rotting vegetation. It grows in cool temperatures and at a pH greater than 5.4 under anaerobic conditions. It thrives in baleage systems when limited fermentation and entry of air results in spoiled, moldy feed. Common places to find Listeria include spoiled silage at the end of trench silos, decaying forage at the bottom of solid feed bunks, and rotting hay or baleage. A very common mistake by producers is feeding too many bales at once. Baleage that sits out open to the air over several days will begin to rot and spoil, allowing bacteria and molds to proliferate. In order to produce clinical disease, Listeria must survive the fermentation process which it can easily do if the pH never goes below 5. Large numbers of bacteria may gain access to the body through the mucous membranes of the mouth (through small cuts) and travel up the nerves to the brainstem. Fever, anorexia (off feed), depression and neurologic signs develop depending on which cranial nerves are affected. Neurologic signs include leaning to one side, stumbling, circling in one direction, facial nerve paralysis, drooling, difficulty chewing, drooped lower jaw, and head tilt. Early intervention with antibiotic therapy is often successful but, if the cow goes down (becomes recumbent), the odds of survival are low despite aggressive treatment. The prognosis for sheep and goats with listeriosis is poor with an approximate 25% survival rate.

“Silage Eye” due to Listeria monocytogenes. Photo: http://www.nadis.org.uk/bulletins/eye-conditions-in-cattle.aspx

Infection with Listeria may also result in eye disorders and abortion. Anterior uveitis or “silage eye” follows conjunctival infection with L. monocytogenes. The symptoms are very similar to pinkeye with tearing, blinking, and sensitivity to light early in the course of disease followed by development of a bluish-white corneal opacity (see photo) then pus and dead cells accumulate just behind the cornea in the anterior chamber. Treatment with long-acting antibiotics should speed healing. Listerial abortion can occur at any stage of pregnancy. The route of infection is through the GI tract into the bloodstream and then to the placenta causing fetal death.

- Bacterial and fungal abortion is another possible consequence of poorly preserved forages. Forage baled and wrapped too dry provides excellent conditions for germination and growth of a variety of yeast, molds and bacteria. Fungal spores are spread throughout the body by the bloodstream after inhalation or ingestion. Germination and growth of fungal spores in the placenta results in abortion, typically in the last 1/3 of pregnancy. If submitted to a diagnostic laboratory, fungal lesions are almost always identifiable in the placenta. Not all molds are dangerous though; many bales will develop some white surface mold due to small holes in the plastic but it does not penetrate deep into the bale. This outer layer can be removed at feed out or the cows will usually avoid eating these areas. Bacterial contamination of baleage results in similar abortion risks. Bacillus species proliferate in poor quality silage and are partly responsible for deterioration when air is allowed in the bale. Bacterial abortion due to Bacillus species occurs when cows ingest the organism which travels through the bloodstream to the uterus followed by growth of the organism in the placenta and fetus. Cows abort in the last month of pregnancy or calves may be born alive but die within 24 hours.

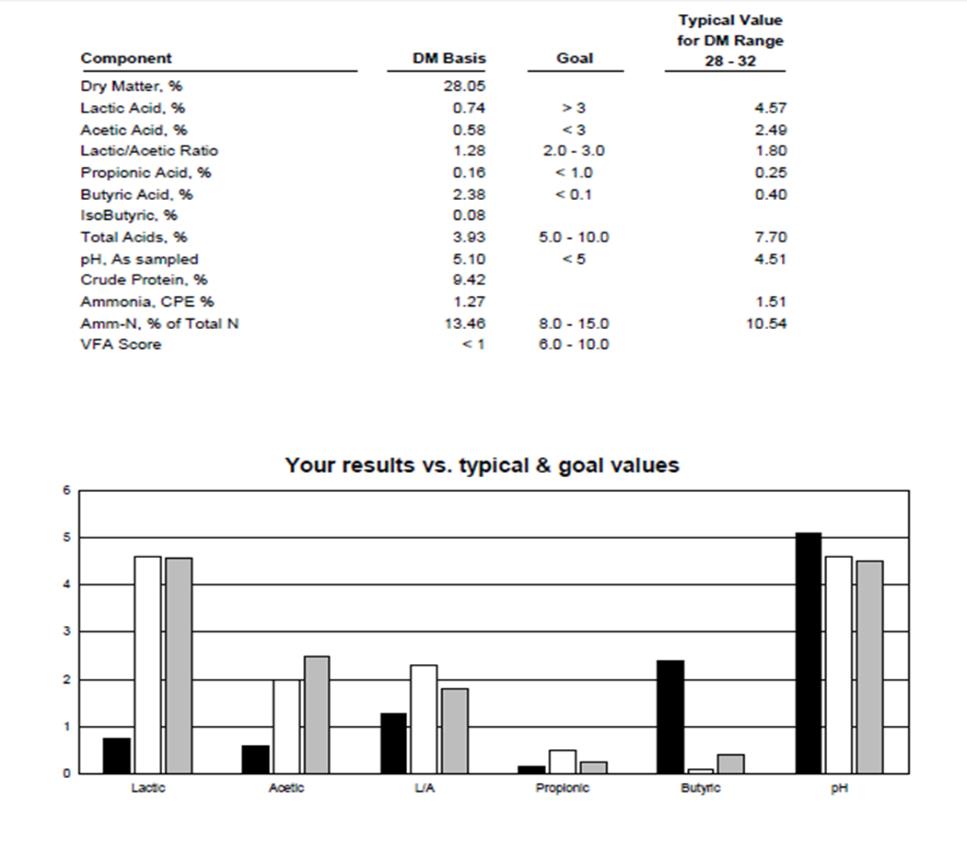

- Poor quality baleage, if not adequately supplemented, will lead to loss of body condition in late gestation and early lactation, poor milk production and poor fertility. The feed value of baleage is a function of forage maturity at harvest, baling, handling and storage. The best method to evaluate baleage is a forage analysis that includes a fermentation profile (see example). Important goals include pH<4.5 ( definitely below 5 ), at least 2% lactic acid and greater than 5% total acids on a dry matter basis, and a volatile fatty acid score (VFA) above 5.

A fermentation report from Dairy One Forage Testing Lab (Ithaca, NY) on a sample of poor quality wheat baleage. Legend: The black bar=your results; white bar=Goal Value; grey bar=typical values

A fermentation report from Dairy One Forage Testing Lab (Ithaca, NY) on a sample of poor quality wheat baleage. Legend: The black bar=your results; white bar=Goal Value; grey bar=typical values

Prevention is based on ensuring proper harvest and preservation of wrapped forages and maintaining proper feedout rates to reduce the risk of growth of organisms dangerous to cattle. Correct moisture content is of primary importance; there is a field method to assess moisture that will yield a general idea of moisture content but there are far more accurate methods available. Cut forage at the proper stage of maturity so it contains adequate levels of fermentable carbohydrates for good ensiling. See Quality Hay Production (AGR-62) for specific cutting recommendations for various forage crops http://www2.ca.uky.edu/agc/pubs/agr/agr62/agr62.htm. Also, achieving the highest bale density possible, especially with high internal core densities, removes the maximum amount of oxygen with few air pockets. Wrapping the bales quickly after baling with a good quality plastic, preferably with an ultraviolet inhibitor and 6-8mm thickness, and using multiple (4-6) layers will extend the storage time. Bale weight can be a safety and equipment issue. Details of proper techniques can be found in the UK Extension Fact Sheet AGR-173 entitled “Baling Forage Crops for Silage” at your local extension office or on the web at http://www2.ca.uky.edu/agc/pubs/agr/agr173/agr173.pdf. Another excellent resource is the UK Forage website for more information: http://www.uky.edu/Ag/Forage/ForagePublications.htm#Silage/Balage0 and look for Baleage:Frequently Asked Questions. Example below of great baleage!

Moisture Testers: Two types of forage moisture testers are available: one type utilizes heat and the other type utilizes electronics. Heat-type moisture testers consist of a heater/fan drying unit, a screen-bottomed sample container, and a simple spring scale. Moisture content is determined by filling the sample container with a fixed amount of wet forage and drying the forage to a constant dry matter percentage. The mass difference between the wet and dry forage is used to determine the initial forage moisture content. Most heat-type moisture testers require 25 to 35 minutes to operate.

Electronic moisture testers provide an instantaneous moisture content reading, but there is some question of their accuracy when testing wet forage (most are made to test hay). Most electronic-type testers are comprised of a sensing probe and a hand-held display unit. The electrical conductance of the forage is measured between two metal contacts at the tip of the probe when inserted into the forage. Testers determine forage moisture content based on the relationship between moisture content and electrical conductivity.

Heat-type moisture testers tend to be more accurate than electronic moisture testers, although results can be affected by many factors including the effects of hay drying agents. Either type of moisture testers can be purchases from agricultural supply houses, such as NASCO, for around $300.

A relatively new technology is a hand-held device that uses Near-Infra-Red (NIR) scanning technology to measure the moisture content of animal feed. This unit comes with software to collect, view, and store recorded measurements.

Microwave Oven Method: The microwave oven method to calculate forage moisture content allows reasonably accurate results to be obtained in a relatively short time. This method takes about 20 minutes to complete. However, the measured moisture content is much more accurate than when using electronic moisture testers.

Before using the microwave oven method, obtain the following items:

- Microwave oven

- Scale (must weigh in grams)

- Microwave safe plate

- 10- to 12-ounce cup of water

- Pencil and paper

Use the following procedure to obtain the best results:

- Obtain a representative forage sample (whole plants).

- Cut the sample into 1-inch pieces; keep leaves and stems uniformly mixed.

- Place a paper towel on the plate.

- Weigh a plate plus 100 grams of forage sample; spread the sample as uniformly as possible.

- Place a 10- to 12-ounce cup of water in the corner of the oven to capture unabsorbed microwaves as the plant tissue dries to prevent potential fire.

- Set oven on HIGH for 5 minutes.

- Weigh sample and plate and record.

- Change the water in the glass.

- Set oven on HIGH for 2 minutes.

- Weigh sample and plate and record.

- Repeat steps 7 through 10 until weight does not change more the 1 gram (this means the sample is dry).

- Percent moisture = 100 grams – final weight grams.

Make sure to heat samples in short intervals to prevent the forage from igniting.