Following the Screening and Scoring Process detailed in the Preliminary R&D Section, the following two designs were carried forward into Advanced R&D and Performance Testing.

Design 1: Bill of Materials

Design 1: Orthographic Views

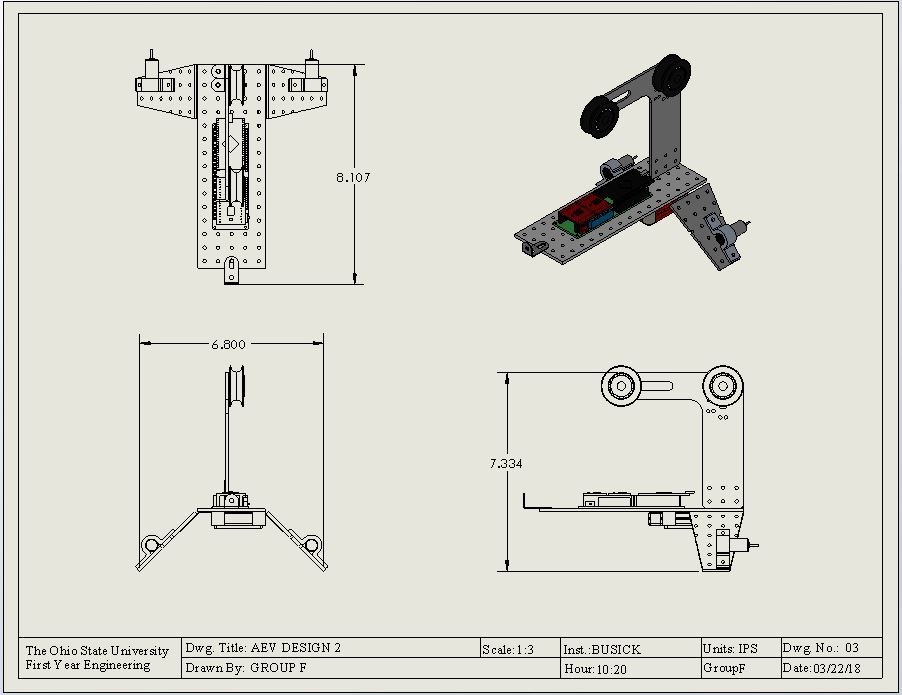

Design 2: Orthographic Views

Design 2: Bill of Materials

Design 2: Bill of Materials

aR&D Design Changes

During Advanced R&D, we compared motor quantity and orientation variations. These tests concluded with the determination that the number and orientation of motors incorporated in Design 2 were ideal. In addition, a study on servo braking by Watts Scientific, Division L prompted our team to add a servo brake to the design.

Performance Testing Design Changes

Due to the findings of aR&D and concerns about the weight and balance of Design 1, our team focused their efforts on improving the design and code for Design 2. A couple modifications arose from the performance testing. Early in the process, position-based code was abandoned due to problems with the reflectance sensors that could not be resolved. As such, the sensors were removed from the AEV design to save cost and weight.

In addition, we added spacers under the bracket that attaches to the caboose in order to better align with the magnetic contact point of the caboose.

Our final design resulted in a compact, lightweight, energy efficient AEV that performed well in final testing.