In an effort to help growers select and grow the best pumpkins for their operation, the Integrated Pest Management Program planted a demonstration trial at the Western Ag Research Station in South Charleston to highlight foliage, handle, fruit size, and fruit quality. There were 20 entries from four companies in the trial, with emphasis placed on hybrids that offered some type of disease resistance, primarily to powdery mildew. The intent of the trial was primarily for growers who attended the pumpkin field day to observe differences in plant and fruit quality in person, in order to generate a visceral opinion and appreciation for the hybrid.

The trial was originally direct seeded June 1st, but due to mice damage and flooding rains, was replanted with transplants June 16th. Approximately 75 pounds of nitrogen was side dressed as liquid 28-0-0 on June 9th, with no P or K applied per soil test recommendations. Strategy and Dual were used pre-emerge to control weeds, with shielded applications of glyphosate followed by hoeing and hand weeding throughout the season. Once powdery mildew was detected in these plots on July 24th, they were sprayed on a 7-10 day schedule with a standard fungicide program that alternated several modes of action, per OSU recommendations.

While specific trial data was collected, because it was not replicated or randomized, all calculations for yield and fruit size should be seen as estimates taken from one site, under a specific set of weather conditions. When making decisions about hybrid selection for 2018, this information should be combined with other trial data from around the state or region. This trial was not irrigated, and received above average rain fall for this location based on historical records.

Group shot of pumpkin hybrid trial, large fruit in top row, medium sized fruit in middle row, and small fruit in bottom row.

To obtain average fruit weight, 3-5 fruit of each hybrid per plot representing the largest, smallest, and average sized fruit were chosen and weighed. All other marketable fruit in plot were counted and used in yield calculation, which was based on a 15’ row spacing, 35’ length of row, with plant spacing 3-4’ apart.

If you have additional questions about the trial, contact me directly at jasinski.4@osu.edu.

Yield data from pumpkin hybrid trial, see above for yield estimates. *indicates reduced stand in trial.

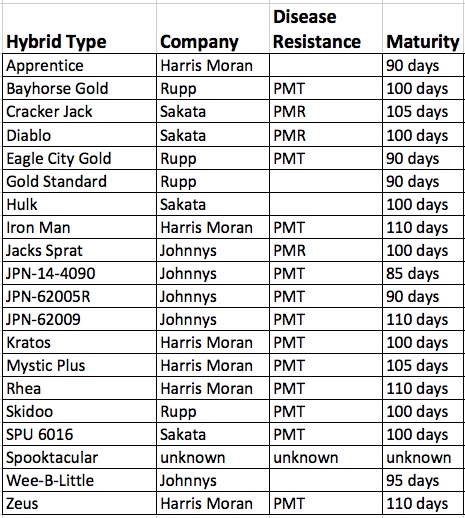

Seed companies and other pumpkin hybrid attributes from 2017 trial. PMR = powdery mildew resistant, PMT = powdery mildew tolerant.