Throughout the history of agricultural mechanics in education, students have been asking this question has fast as teachers have been trying to figure what objectives to teach in a vocational agriculture program. Because the scope of farm and homework continued to change with different advancements and technologies (i.e. farm machinery and electricity), agriculture teachers have to revise their curriculum in order to keep up-to-date with society. With endless amount of job opportunities in industry, the skills that students have learned in an Ag Mech course has led them to immediate employment after graduation.

Agricultural education programs have always had a strong involvement in their communities, and as a result, their curricula would change based on community needs. Involving the community into the curriculum is a common practice that exist today. Teachers will create an advisory committee that consist of local industry professionals, school administration, FFA members, and other teachers who will helped design a curriculum that best suit for the students living in their communities This is a valuable practice of connecting industry, community, and education.

When I did my first Early Field Experience in agriscience education at Marysville High School, I had the opportunity to observe first-hand an “Advisory Committee Meeting.” This committee consisted of teachers, school administrations, industry professional, and community members, and they collaborate on designing a curriculum and course sequence met the goals of the students and community. This was an incredible opportunity to see the impact that an agricultural education program can have on students when people come together to better education.

Agricultural Mechanics Curriculum in the 1910s

What did students learn in school in the early 20th century?

Agricultural Mechanics Curriculum in the 1930-40s

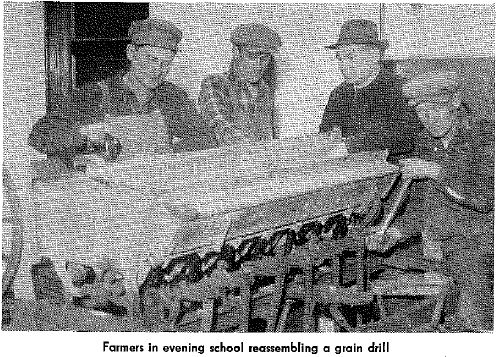

During and after World War II, there was a demand for farmers to increase food production, yet National Defense slowed down production on farm machinery. This was a challenge that many farmers weren’t prepared for because they were short laborers, functional farm machinery, and knowledge to upkeep and repair their equipment. Vocational agriculture became a pathway for farmers to meet these demands through the offering of “defense classes” or “farm machinery repair clinics,” which were courses offered to local farmers on metalworking, woodworking, electricity, and machinery repair and maintenance. This is the method of deliver the modern-day practices to farmers. Because the teacher developed a connection with the community through these courses, the teacher had a better opportunity to create his own objectives for teaching farm mechanics. A farm mechanics course in the 1930-40s consisted of classroom learning and field experience that allowed students to practice:

Agricultural Mechanics Curriculum in the 1970s

As the 1970s began, career technical education focused curriculum in the areas of vocational education, general education, and college preparatory, which prepared ‘youngsters’ for a wide range of job options. Regardless of a student’s educational pathway, people believed it was still vital for students to learn basic agricultural mechanical skills, especially if they were interested in production agriculture.

How was an Ag Mech curriculum taught in the 1970s? What skills were necessary to teach? Wiley B. Lewis, a PhD graduate from The Ohio State University, Department of Agricultural Education in 1972, conducted his research on “Agricultural mechanics as performed on Ohio farms in comparison with offerings in vocational agriculture.” His researched reveal that students were most successful when they were provided with an individualized instruction and curriculum. At first glance, this would seem to be a challenging task for an Ag teacher; however, this practice was successful when integrating student’s individual curriculum with the department’s curriculum and with the student’s Supervised Agricultural Experience (SAE) projects. Individualized instruction became a necessity in teaching agricultural mechanics.

A model representing individualized instruction in agricultural education.

Examples of Content Priorities in Agricultural Mechanics Source: C. Don Knotts & Earl S. Wobb, The Agricultural Education Magazine, 1974

Agricultural Mechanics Curriculum in the 2010s

During the first 10 years of the 21st century, agricultural education transitions away from Ag Mech and shift their focus on agrisciences. Nevertheless, the pendulum swung back around and Ag Mech became major corner stone in the curriculum. With the growth of STEM (Science, Technology, Engineering, and Mathematics) in education in agricultural education, agricultural mechanics had an incredible opportunity to expand their curriculum. Undoubtedly, STEM has always been major pillars in an Ag Mech curriculum.

In today’s modern world in agricultural education, students are learning applications essential to machinery management, structures, soil and water management, and material handling systems. Students are prepared to understand the theory and practical skills needed on production farms. With the rise in agricultural production, sales, and processing, there is a great demand to train students and adult for careers in mechanic technicians.

This is a following description of the “mechanical principles” course taught today in Ohio’s agricultural education:

Students will engage in the mechanical principles utilized in animal and plant production systems. They will learn electrical theory, design, wiring, hydraulic and pneumatic theory, along with metallurgy in relation to hot and cold metals. Students will apply knowledge of sheet metal fabrication applicable to the agricultural industry along with identify, diagnose, and maintain small air-cooled engines. Throughout the course, students will learn critical components of site and personal safety as well as communication and leadership skills (Ohio Department of Education).

Kids love to weld! Students who want to pursue careers in mechanical principles take multiple courses in order to have skills to enter the workforce. Welding, for example, students have to complete a basic welding course that prepares students in SMAW (stick), Oxyfuel, and MIG and learn to cut metal with Oxy-acetylene and plasma cutter. Once they learn the basic skills, they take advance courses in metal fabrication where they explore concepts like the different variables affecting welding, American Welding Specifications, and the chemistry of metals at a deeper level.

What does the future hold?

The United States is facing large skilled labor shortages, and we are needing people to enter careers in welding, construction, electrical, and much more. The American Welding Society predicts that the industry will need 290,000 people to fill welding job positions. The U.S. Bureau of Labor projects that there will be 50,000 new jobs in diesel mechanics. Society will soon be facing the reality that there won’t be enough people to be service technicians for dealerships and welders for manufacturing.

With that, agricultural education is one piece of the puzzle in solving these problems by continuing to teach agricultural mechanics and ‘farm shop’ in their curriculum. Agricultural education is more than capable in preparing secondary education students with the essential knowledge and skills to be career ready and successful in the real world.