Prevention of sour sap is all about sanitation. Here are a few things to consider when developing a sanitation plan for your maple operation. As soon as the previous season ends, producers using tubing need to clean and sanitize their lines. There are many ways to do this, but the most important thing is to make sure it gets done. As the new season approaches, inspect your lines for sanitation problems, consider replacing not only the spouts but the drops and tees if needed. As the new season begins, producers using high vacuum should consider running your vacuum 24/7 to keep your lines clean, clear, and cool. During the season, make sure you wash your holding tanks often to prevent microbial scum buildup.

Where sap is held for a long period of time, avoid using plastic tanks for long term sap storage. Plastic is porous and retains bacterial inoculum that will quickly generate bacterial growth. These plastic tanks are often referred to as commercializers, named after the old commercial grade of syrup that nobody wanted. Once a plastic tank becomes contaminated, they are almost impossible to clean and should be replaced.

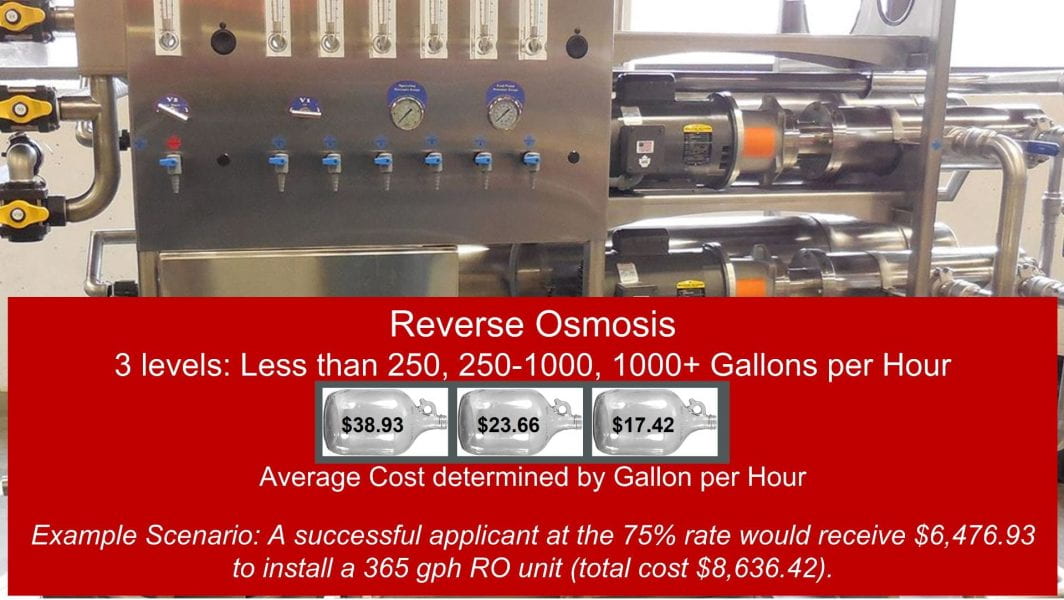

In the sugarhouse, making quality maple syrup starts with your reverse osmosis (RO) unit. Concentrate must be evaporated as soon as it comes off the RO. Bacteria multiply quickly in concentrated sap. This is the result of a higher percentage of sugar in the concentrate. There is also an increase in the sap temperature as it moves through the RO. It may enter the RO at 40 degrees F or less, but when it comes out, it will be closer to 50 degrees F. High Brix concentrate, elevated sap temperatures, and a warm sugarhouse are the perfect recipe for taking good sap and turning it into a microbial cesspool if not careful. This is one of the reasons many producers are now considering using refrigerated milk bulk tanks to store concentrate. This cools the concentrate and allows more time to manage the boiling process.

Producers often accept the fact that concentrate left on the evaporator overnight will produce a darker grade syrup, at least until fresh sap is introduced. This does not have to happen if managed properly. Small evaporators should be drained if possible. Larger evaporators can be equipped with a wash system that allow the entire evaporator to be cleaned and drained. Once the syrup leaves the evaporator, the process of sanitation continues. Syrup should be filtered and placed in a stainless-steel drum after being reheated to at least 180 degrees F. There is an inherent risk when you attempt to drum syrup at lower temperatures. Spoilage happens when barrels are packed at low temperatures. The hot syrup and cold barrel causes condensation (H2O) which combines with the remaining air in the barrel ultimately resulting in mold and fermentation. It is best practice to place filled barrels in a cool place like a basement or a barn that does not heat up. Another practice worth looking into, is to build a cool room by equipping a small insulated room with an air conditioner.

When you re-open a barrel of syrup, you should have syrup that is ready to bottle. When you bottle your syrup bring the syrup back up to 185 degrees for packing. Syrup packed below 185 F is subject to spoilage and reduced shelf life. Going above 190 also creates several problems. And if the syrup peaks above 200 F, the syrup will start to foam, and niter will start precipitate. The only solution for this scenario is to filter the syrup again. You will also overheat your jugs causing them to contract and suck in if they are not 100% filled. Plastic jugs should always be filled within a half inch of the top and laid on their side to kill any bacterial that may have found its way in the jug. If you pack in glass bottles, make sure you put your bottles in the oven at 200 degrees for a few minutes. Hot glass will not condensate moisture and you can eliminate most problems with this simple step. It is always good to pack several times over the course of the year to maintain the highest quality in your syrup.

Many years ago, there was a use for commercial outlet for sub-standard syrup. The majority was sold to the tobacco industry. It was used to sweeten chewing tobacco. That outlet for the most part no longer exists. There are places where substandard syrup could be used but its objectionable flavor drastically lowers its value. For this reason, there is now a movement to prevent this type of syrup from getting into the market. Bulk buyers no longer want to handle sub-standard syrup and if they buy it they are not going to pay very much for the product. In addition, there is a currently an effort by the International Maple Syrup Institute and others to promote educational programing to raise producer awareness about ways to avoid producing this kind of syrup. The reality is that there is very little economic return from sub-standard syrup production. With rising costs of equipment and inputs the production of anything less than top quality saleable syrup in today’s high demand market is foolish.

There you have it – a 4-part series starting with a lesson on phenology and how to track growing degree days, relating growing degree days to tree bud development, appreciating the differences between buddy sap and sour sap, taking sanitation seriously at every single phase, and PRESTO! viola! alakazam (if only it were that easy!!) – you are making QUALITY maple syrup!