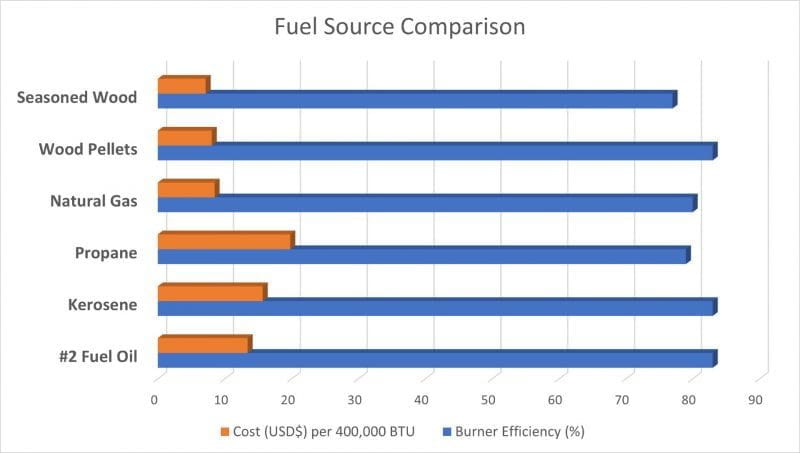

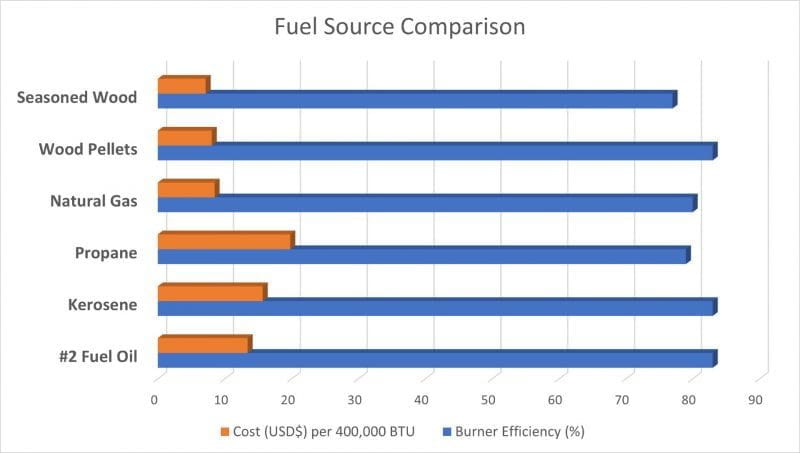

When it comes to selecting a fuel source for your evaporator, operators should choose based on efficiency, not convenience. To convert 2% sap into 66 brix syrup, 400,000 BTU are required – this is constant for all fuel sources. The two most popular fuel sources, in today’s maple world, are wood and fuel oil. Additional choices include natural gas, liquefied petroleum (LP) gas, and various wood products such as pellets have been adapted to fuel maple evaporators.

I created the above figure based on estimates generated from the Southern Maine Renewable Fuels Institute. Based on the statistic above – 400,000 BTU are required to produce a gallon of syrup – I derived production cost estimates for each fuel source and compared burner efficiency. Fossil fuels have a slight edge when it comes to fuel efficiency. The reason they are so efficient is based on the type of burners used and the ability to extract a higher percentage of heating units from each fuel source.

How do you choose the right fuel source for your maple operation?

The ambiance of making syrup on a roaring wood fire has never been challenged. Wood is by far the most popular fuel source for evaporators. It is readily available. And most producers look at dead wood scattered about the sugarbush as something that needs to be disposed of anyway. For that reason, the true value of wood is seldom considered. As we will see later, the value of wood is very close to the value of fuel oil when it comes to making syrup. The true value of wood is based on the dollar value of cordwood. There is an old saying “cordwood has no value until it cut and stacked.” Its value is representative of your time and labor.

A standard evaporator will produce 22 gallons of syrup from a cord of dry wood. Without the major advances in wood burning technology, most open evaporators are rated at 40-60% efficiency. Heat units are lost at multiple locations across the evaporator. You can quickly see why many producers made the shift to more efficient oil evaporators even though they now had to pay for fuel. The efficiency of a wood-fired evaporator is in the design. No matter what the design, the basic principle of operation remains the same. A wood-fired evaporator draws heat from the flame produced in the firebox. The heat consisting of flame and burning gases is drawn by air movement under the pans and out the stack. The arch is designed to pull and lift the flame up a moderate incline eventually compressing the heat into the flues of the rear pan. The heat exits the evaporator through the stack at temperatures of 600-800 degrees F. Stack dimensions must be designed correctly for proper draft. Wood needs to be placed in the evaporator to facilitate maximum heat without choking the air and dampening the flame. This usually means the firebox should not be filled to the top. You need to allow space for air to enhance the flame. The wood should be fired at regular intervals. A general recommendation is every 5 minutes.

There have been many changes in modern wood arch design that increase the overall efficiency of the evaporator. Forced air injection along with highly insulated arches and firing doors make the modern wood-fired evaporator as efficient as their oil-fired counterparts. Some are rated 85-90% percent efficient. Such high-performance levels are the result of being able to totally burn the wood that is loaded and the ability to re-burn gasses given off during the combustion process (gassification).

Fuel oil is another popular choice among maple producers, and there are several reasons for this. Fuel oil burns clean and hot and is an ideal choice for larger operations that require high volumes of fuel. This logic has been tempered in recent years with the increasing use of reverse osmosis to produce high Brix concentrate and reduce fuel demands. Efficiency is relatively high nearing 80%, and 1 gallon of syrup can be produced for under 4 gallons of fuel oil.

Bio-diesel Evaporator.

Unlike wood-fired arches, oil-fired evaporators require a minimal draft. Oil-fired arches are designed to develop radiant heat. The burner flame creates a ball of radiant heat and that heat then hovers beneath the pans. Temperatures in an oil arch can reach 1000 degrees F. The movement and intensity of the heat is controlled by a barometric damper that restricts the movement of air through the stack. The damper maintains a uniform temperature by controlling the airflow thru the evaporator. If this control device is not present, the heat can quickly be lost up the stack and the performance of the machine will be impaired. The burner nozzle size and fire rate determine the intensity of the heat. If everything is working correctly, the flame will burn cleanly and the flame ball of burning fuel oil will be suspended in the middle of the fire box never touching the sides of the arch.

Natural gas is very similar to fuel oil. In fact, the burners today are very similar in operation. Natural gas is convenient and is probably a cleaner source of fuel than oil; additionally, efficiency mirrors fuel oil. Though the original natural gas burners were often inconsistent resulting in hot and cold spots across the pans, there is now little difference in performance as compared to oil-fired evaporators. The biggest drawback is the availability of natural gas. Unlike oil that can be hauled to a remote location, gas needs to be piped in and is not readily available everywhere. If you are fortunate enough to have natural gas available, it is an excellent fuel option.

Natural Gas Evaporator.

The biggest drawback for oil and gas is the variability in cost as the oil market fluctuates. In 2020, we are living in a down cycle for oil and gas and prices are more appealing entering the 2021 syrup season. Within a few years, that could be a completely different story. Time will tell.

I would be remiss if I stopped the article there.

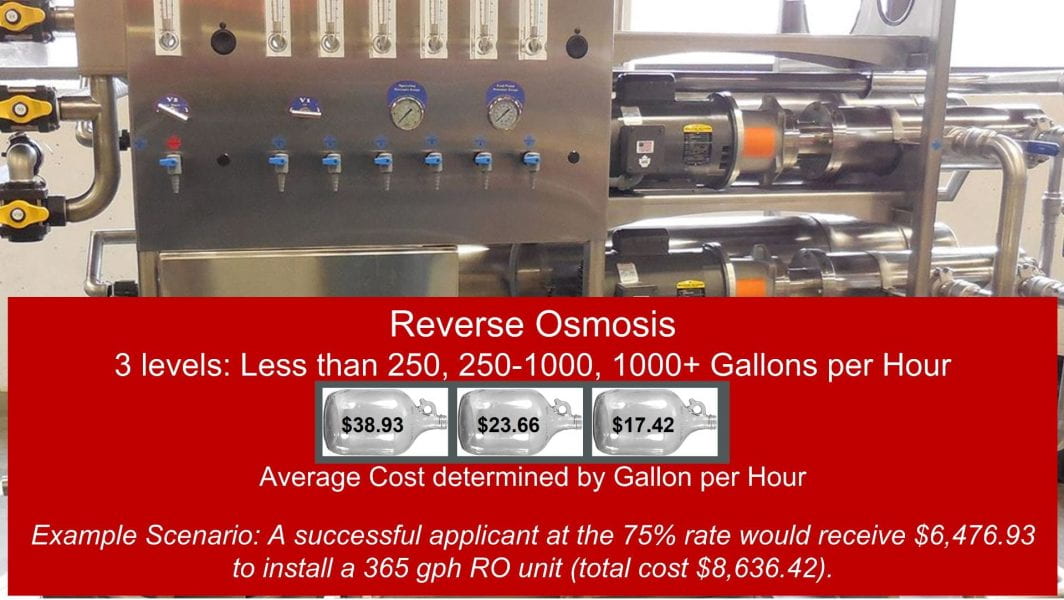

Regardless of what fuel source you choose for making maple syrup, the best single investment a producer can make is to add reverse osmosis to their operation. Despite the high initial cost of reverse osmosis, the cost of processing syrup is reduced significantly and the pay-off is long-term. Reverse osmosis not only allows a producer to process sap quicker, but it also opens the door to expand one’s operation. The savings on fuel are obvious. Before ROs, as reverse osmosis is commonly called, became popular the size of the operation was limited to the amount of sap that could be boiled on an evaporator. The only way to add capacity was to add evaporators, and some of the larger operations were running four, five, and even six to handle peak sap flow. Today, those same operations now employ modern RO systems with multiple membranes that can handle sap coming from thousands of taps. And using less time and space to do so. Reverse osmosis revolutionized the North America Maple Industry.

Author: Les Ober, Geauga County OSU Extension