Hello all! I thought it was time for another update!

So over the past couple of weeks we set out for what we needed to do in the Wine Room. First we walked through the room and learned what the operators do. Then we starting tracing the lines and updating the redlines, followed by labeling the pipes. This strategy worked out pretty well–as we had a strong idea of the process of the area moving forward with the project.

Many things were added to the drawings–including new lines, flow directions, valves, and any missed instrumentation. For each sheet, all individual lines and valves were named as well. In the future this will greatly help out anyone who is writing or following a standard operating procedure to be able to say “For this transaction product will flow from line LBB 3089-25 to LBB 3089-28. Open valve LBB-3089-5.” Each line was named according to the following setup:

Product-Nominal Pipe Size- Sheet Number-Pipe Material- Line Number

EX: W-3″-3089-SA 312- 22

The valves also follow a similar set up. This allows anyone looking at the P&ID drawings to instantly identify the product going through the pipe, the material of the pipe, and the pipe size.

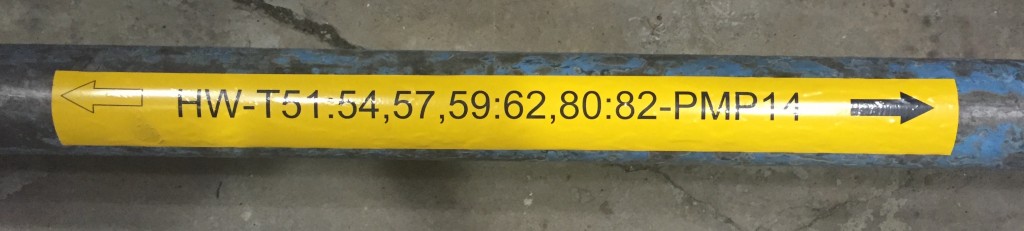

Moving forwarded with the labeling was difficult. As with the rest of the plant, the Wine Room has a lot of pipes that the operators use every day, and some that they have not touched in the four years on the job. We had to find a balance in labeling. We’d ask ourselves, okay, might this line be helpful if they need to transfer something in the future? Also, how much information is too much? We analyzed the redline drawings, and generated an approach. On each pipe, the following information is spelled out:

Product-From-To (and direction of flow)

We also realized partway through that pipes *could* flow in two directions, but typically only went one way as in the example below:

Another challenge we ran into was how to denote pipes which had main flows going two different ways. How do we show where it is coming from and going to? How do we keep it consistent with the current format? Eventually we decided to simply split the label into two different parts, each showings the flow of one direction of the pipe, and the associated information for that pathway as seen below.

On the left, you see that the contents of the pipe are a high wine. When the product is going left is is coming from pump 22 and going to pump 16. When product is traveling right through the pipe it is coming from the Tank Farm and going to tanks 51 and 59. Bold arrows are used in both directions because the pipe has a primary purpose both ways.

That is basically it!