Final AEV Design

Our final AEV design and code possess several advantages. By using an average number of 206.7 Joules per run in under 60 seconds and minimizing the number of parts on the AEV, efficiency and cost are its strengths.

Efficiency:

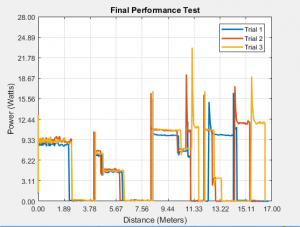

As seen in the graphs below, our AEV design consistently performed at a very low energy level in about 60 seconds. Averaging at 206.7 Joules, that is equivalent to about 3.4 J/s. This efficiency will minimize the costs of the vehicle, allowing the city of Columbus to use the money they save for other improvements.

Cost:

Because the AEV’s final design did not use custom parts, the final cost of design totaled under $156,000. Additionally, with an accuracy error of only 1.11, the final cost was only $607,692.78. This sleek design is a great investment in the community, allowing extra resources to be used for other areas of improvement.

| RUN 1 | RUN 2 | RUN 3 | |

| Capital Costs | $ 155,660 | $ 155,660 | $ 155,660 |

| Energy Costs | $ 228,417 | $ 227,353 | $ 229,306 |

| Time Costs | $ 180,000 | $ 178,500 | $ 178,500 |

| Accuracy Penalty | 1.25 | 1.111111111 | 1.111111111 |

| R&D Costs | $ – | $ – | $ – |

| Safety Violations | $ – | $ – | $ – |

| TOTAL COST | $ 666,181.25 | $ 606,607.78 | $ 608,777.78 |

Power vs. Time of Final Performance Tests

| AEV Final Design Cost | ||||

| Unit Cost | # Used | Cost | ||

|

Propulsion System

|

Arduino | $ 100,000 | 1 | $ 100,000 |

| Electric Motors | $ 9,900 | 2 | $ 19,800 | |

| Servo Motors | $ 5,950 | $ – | ||

| Count Sensor | $ 2,000 | 2 | $ 4,000 | |

| Count Sensor Connector | $ 2,000 | 2 | $ 4,000 | |

| Propellers | $ 450 | 2 | $ 900 | |

|

Body Structure

|

T- Shape | $ 2,000 | 1 | $ 2,000 |

| X- Shape | $ 2,000 | $ – | ||

| 2″ x 6″ Rectangle | $ 2,000 | $ – | ||

| 2.5″ x 7.5″ Rectangle | $ 2,000 | $ – | ||

| 1″ x 3″ Rectangle | $ 1,000 | $ – | ||

| 1.5″ x 3″ Rectangle | $ 1,000 | $ – | ||

| Trapezoids | $ 1,000 | $ – | ||

| L-Shape Arm | $ 3,000 | $ – | ||

| T-Shape Arm | $ 3,000 | 1 | $ 3,000 | |

| Wheels | $ 7,500 | 2 | $ 15,000 | |

| Battery Supports | $ 1,000 | 2 | $ 2,000 | |

|

Brackets & Tools

|

Angle Brackets | $ 840 | 3 | $ 2,520 |

| Screw Driver | $ 2,000 | $ – | ||

| 1/4″ Wrench | $ 2,000 | $ – | ||

| Motor Clamps | $ 590 | 2 | $ 1,180 | |

| #55 A Slotted Strip, 2″ | $ 1,260 | 1 | $ 1,260 | |

| TOTAL: | $ 155,660 | |||

Time:

In every test, including the unused first trial of final performance testing, the AEV completed the run in 60 seconds or less. This pace, while minimizing the amount of power needed, allows the passengers to arrive at their destination in a small amount of time. This increases customer satisfaction, which is great for the city.

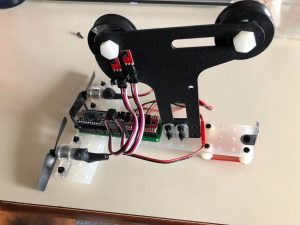

Aesthetics:

The sleek design is low weight and eliminated wasted space. The wires are organized and the arduino fits perfectly on the T-shape base. This aesthetically pleasing model will improve the image of Columbus, keeping its reputation of a modern, beautiful city.

Click here to see Final AEV Design in action!