Preliminary Research and Development

Maria:

The most important feature of this design is the change in shape of the front of the base through the use of a laser cutter. The triangle shape allows the AEV to be more aerodynamic, increasing the efficiency, while also decreasing the weight of the project.

Daniel:

This design has a big importance on aerodynamics and power. While it may not be the lightest AEV, it has a lot of power coming from the two motors and the wings on the side allow the AEV to avoid air resistance. Increasing the power and aerodynamics of the AEV allows for more control of when the car moves and stops.

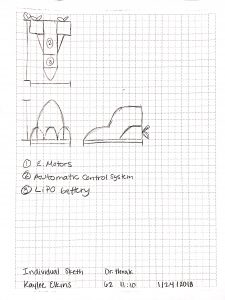

Kaylee:

The key feature of this design is its smooth curves and edges to maximize its aerodynamic properties. Both propellers are kept in this design to maximize speed. To compensate for this, all unnecessary weight will be cut out, such as unnecessary plastic for the initial construction of the AEV.

Group Design:

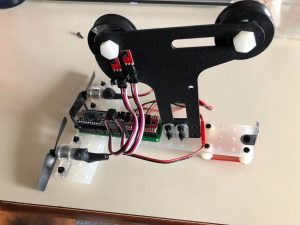

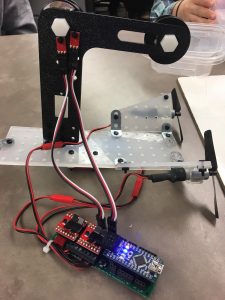

There are several key aspects of the combined design. Using the concept of laser cutting the front of the base, the AEV will be lighter and more aerodynamic. Expanding upon this concept, the wings will be cut to might the design lighter and rounded 3D-printed “cups” will be added around the end of the motors. The final change will be switching the mounting bar from an “L” shape to the “T” shape will aid the center of balance.

Performance Testing

Performance Test One

In Performance Test One, two different designs were tested for efficiency. Based on the information gathered in Advanced Research and Development (found under deliverables), the 3030 propellers were used in both designs with a push configuration on the first half of the track. The key difference between the designs is the base of each AEV. In the first design, the standard rectangular base was used with two wings. In the second design, the T-shaped base was used. Eliminating the additional wings and brackets eliminates cost and weight. The L-shaped arm was also exchanged for a T-shape design to change the center of mass, balancing the AEV on the track, making it more consistent.

Design One

Most importantly, their efficiency was compared in using the following code for performance test one. It was found that the second code ran more efficiently with this same code. It used a lower average amount of watts per meter traveled. The graphs compared are seen below. This was a major determining factor in the decision to move forward with the second design over the first.

Code Used With Successful Completion of Design One:

reverse(4); //Reverse both motors

motorSpeed(4,35); //Set both motors to 35% power

goToAbsolutePosition(200); //Stop 200 marks from the starting point

brake(4); //Brake both motors

motorSpeed(4,0); goFor(11); //Both motors at 0% power for 11 seconds at stop sign

motorSpeed(4,25); goFor(5); //Set both motors to 25% power for 5 seconds

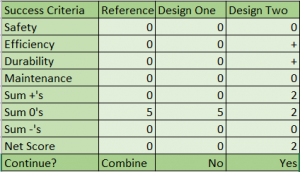

These comparisons are outlined in the Concept Screening and Scoring Charts below based on the reference AEV design, design one, and design two. The final cost of Design Two can be seen in the “Marketing” tab of the website.

Performance Test Two

Performance Test Two was more challenging as the increased distance allowed for more potential instances of error. After running several trials to find a working code to test, in the first attempt of completing the test, the AEV traveled too far at the gate and failed. Between the first and second attempt, the code was adjusted to travel 170 marks, running successful but barel making it to the stop sign. In attempts to allow the battery to cool, five minutes were allowed before the next test. However, instead of being too short, the AEV again went too long. The following codes used are shown below.

Attempt One Code:

reverse(4); //Reverse both motors

motorSpeed(4,35); //Set both motors to 35% power

goToAbsolutePosition(178); //Stop 178 marks from the starting point

brake(4); //Brake both motors at stop sign

motorSpeed(4,0); goFor(11); //Set both motors to 0% power for 11 seconds at stop sign

motorSpeed(4,25); goFor(5.2); //Set both motors to 25% power for 5.2 seconds

motorSpeed(4,0); goFor(5); //Set both motors to 0% power for five seconds at end of track

reverse(4); //Reverse both motors

motorSpeed(4,20); goFor(1); //Set both motors to 20% power for 1 second, slowing AEV

motorSpeed(4,0); goFor(9); //Set both motors to 0% for 9 seconds waiting at end of track

motorSpeed(4,45); goFor(5); //Set both motors to 45% for 5 seconds attached to caboose

Successful Attempt Between Trials Code:

reverse(4); //Reverse both motors

motorSpeed(4,35); //Set both motors to 35% power

goToAbsolutePosition(170); //Stop 170 marks from the starting point

brake(4); //Brake both motors at stop sign

motorSpeed(4,0); goFor(11); //Set both motors to 0% power for 11 seconds at stop sign

motorSpeed(4,25); goFor(5.2); //Set both motors to 25% power for 5.2 seconds

motorSpeed(4,0); goFor(10); //Set both motors to 0% for 10 seconds waiting at end of track

reverse(4); //Reverse both motors

motorSpeed(4,45); goFor(5); //Set both motors to 45% for 5 seconds attached to caboose

Attempt Two Code:

reverse(4); //Reverse both motors

motorSpeed(4,35); //Set both motors to 35% power

goToAbsolutePosition(173); //Stop 173 marks from the starting point

brake(4); //Brake both motors at stop sign

motorSpeed(4,0); goFor(11); //Set both motors to 0% power for 11 seconds at stop sign

motorSpeed(4,24); goFor(5); //Set both motors to 24% power for 5 seconds

motorSpeed(4,0); goFor(10); //Set both motors to 0% for 10 seconds waiting at end of track

reverse(4); //Reverse both motors

motorSpeed(4,45); goFor(5); //Set both motors to 45% for 5 seconds attached to caboose

Final Performance Test

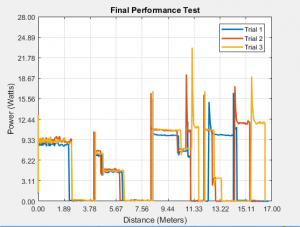

In the final performance tests, trials two and three were used to determine the final cost. In the first trial, the AEV was unable to make it up the hill on the way back to the station after the caboose was attached. This resulted in a significant number of points deducted of accuracy. In the second trial, the AEV had to be stopped at the stop sign on the path to the caboose and again did not make it up the hill, but it was pulled forward to the gate in time for the rest of the task to be completed. However, the AEV ended slightly too far, decreasing accuracy. In the final performance test, the AEV completed a task similar to that of the second run, but stopped at the end of the track correctly. The average energy of the three runs was 206.7 Joules and the final capital costs of the design was $155,660. Using only the results of run 2 and 3, the average cost of the AEV was $607,692.78. These results are summarized in the table and graphs below. The code used for each run can also been seen.

| RUN #1 | RUN #2 | RUN #3 | |||

| ACCURACY PENALTY | ACCURACY PENALTY | ACCURACY PENALTY | |||

| TOTAL SCORE (out of 40) | 32 | TOTAL SCORE (out of 40) | 36 | TOTAL SCORE (out of 40) | 36 |

| ACCURACY PENALTY | 1.25 | ACCURACY PENALTY | 1.111111111 | ACCURACY PENALTY | 1.111111111 |

| ENERGY COSTS: | ENERGY COSTS: | ENERGY COSTS: | |||

| baseline fee + $500/Joule | baseline fee + $500/Joule | baseline fee + $500/Joule | |||

| Baseline Fee: | $ 125,000.00 | Baseline Fee: | $ 125,000.00 | Baseline Fee: | $ 125,000.00 |

| Total Joules from PT: | 206.834 | Total Joules from PT: | 204.706 | Total Joules from PT: | 208.612 |

| Cost from Joules used | $ 103,417.00 | Cost from Joules used | $ 102,353.00 | Cost from Joules used | $ 104,306.00 |

| Total Energy Cost: | $ 228,417.00 | Total Energy Cost: | $ 227,353.00 | Total Energy Cost: | $ 229,306.00 |

| TIME COSTS: | TIME COSTS: | TIME COSTS: | |||

| baseline fee + $1.5K/second | baseline fee + $1.5K/second | baseline fee + $1.5K/second | |||

| Baseline Fee: | $ 90,000.00 | Baseline Fee: | $ 90,000.00 | Baseline Fee: | $ 90,000.00 |

| Total run time in seconds: | 60 | Total run time in seconds: | 59 | Total run time in seconds: | 59 |

| Cost from time used | $ 90,000.00 | Cost from time used | $ 88,500.00 | Cost from time used | $ 88,500.00 |

| Total Time Cost: | $ 180,000.00 | Total Time Cost: | $ 178,500.00 | Total Time Cost: | $ 178,500.00 |

Test One:

reverse(4); //Reverse both motors

motorSpeed(4,35); //Set both motors to 35% speed

goToAbsolutePosition(176); //Move 176 marks from starting position

brake(4); //Brake both motors

motorSpeed(4,0); goFor(11); //Allow both motors to coast for 11 seconds

motorSpeed(4,30); goFor(2); //Set motor speed to 30% for 2 seconds

motorSpeed(4,21); goFor(2.6); //Set motor speed to 21% for 2.6 seconds

motorSpeed(4,0); goFor(10); //Allow motor to coast for 10 secondsreverse(4); //Reverse both motors

motorSpeed(4,45); goFor(5.75); //Set motor speed to 45% for 5.75 seconds

motorSpeed(4,35); goFor(1.85); //Set motor speed to 35% for 1.85 seconds

brake(4); //Brake both motors

reverse(4); //Reverse both motors

motorSpeed(4,30); goFor(1.5); //Set motor speed to 30% for 1.5 seconds

reverse(4); //Reverse both motors

motorSpeed(4,0); goFor(9); //Allow to coast for 9 seconds

motorSpeed(4,45); goFor(3.75); //Set motor speed to 45% for 3.75 seconds

motorSpeed(4,20); goFor(0.5); //Set motor speed to 20% for 0.5 seconds

motorSpeed(4,0); goFor(3.3); //Allow to coast for 3.3 seconds

brake(4); //Brake both motors

reverse(4); //Reverse both motors

motorSpeed(4,45); goFor(2); //Set motor speed to 45% for 2 seconds

Test Two:

reverse(4); //Reverse both motors

motorSpeed(4,35); //Set both motors to 35% speed

goToAbsolutePosition(196); //Move 196 marks from starting position

brake(4); //Brake both motors

motorSpeed(4,0); goFor(11); //Allow both motors to coast for 11 secondsmotorSpeed(4,30); goFor(2.35); //Set motor speed to 30% for 2.35 seconds

motorSpeed(4,21); goFor(3); //Set motor speed to 21% for 3 seconds

motorSpeed(4,0); goFor(10); //Allow motor to coast for 10 secondsreverse(4); //Reverse both motors

motorSpeed(4,45); goFor(4.9); //Set motor speed to 45% for 4.9 seconds

motorSpeed(4,35); goFor(1); //Set motor speed to 35% for 1 seconds

brake(4); //Brake both motors

reverse(4); //Reverse both motors

motorSpeed(4,40); goFor(1.5); //Set motor speed to 40% for 1.5 seconds

reverse(4); //Reverse both motors

motorSpeed(4,0); goFor(9); //Allow to coast for 9 secondsmotorSpeed(4,45); goFor(2.7); //Set motor speed to 45% for 2.7 seconds

motorSpeed(4,20); goFor(0.5); //Set motor speed to 20% for 0.5 seconds

motorSpeed(4,0); goFor(3.3); //Allow to coast for 3.3 seconds

brake(4); //Brake both motors

reverse(4); //Reverse both motors

motorSpeed(4,45); goFor(2); //Set motor speed to 45% for 2 seconds

Test Three:

reverse(4); //Reverse both motors

motorSpeed(4,35); //Set both motors to 35% speed

goToAbsolutePosition(196); //Move 196 marks from starting position

brake(4); //Brake both motors

motorSpeed(4,0); goFor(11); //Allow both motors to coast for 11 seconds

motorSpeed(4,30); goFor(2.35); //Set motor speed to 30% for 2.35 seconds

motorSpeed(4,21); goFor(2.8); //Set motor speed to 21% for 2.8 seconds

motorSpeed(4,0); goFor(10); //Allow motor to coast for 10 secondsreverse(4); //Reverse both motors

motorSpeed(4,45); goFor(5); //Set motor speed to 45% for 5 seconds

motorSpeed(4,35); goFor(1.2); //Set motor speed to 35% for 1.2 seconds

brake(4); //Brake both motors

reverse(4); //Reverse both motors

motorSpeed(4,40); goFor(1.5); //Set motor speed to 40% for 1.5 seconds

reverse(4); //Reverse both motors

motorSpeed(4,0); goFor(9); //Allow to coast for 9 secondsmotorSpeed(4,45); goFor(2.7); //Set motor speed to 45% for 2.7 seconds

motorSpeed(4,20); goFor(1); //Set motor speed to 20% for 1 second

motorSpeed(4,0); goFor(3.2); //Allow to coast for 3.2 seconds

brake(4); //Brake both motors

reverse(4); //Reverse both motors

motorSpeed(4,45); goFor(2); //Set motor speed to 45% for 2 seconds