Energy, water and nutrient impacts of California-grown vegetables compared to controlled environmental agriculture systems in Atlanta, GA

Steven W. Van Ginkel, Thomas Igou, Yongsheng Chen*School of Civil and Environmental Engineering, Georgia Institute of Technology, 200 Bobby Dodd Way, Atlanta, GA 30332, United States.

Citation

Van Ginkel, S.W., T. Igou, and Y. Chen. 2017. Energy, water and nutrient impacts of California-grown vegetables compared to controlled environmental agriculture systems in Atlanta, GA. Resources, Conservation and Recycling 122:319-325. Https://doi.org/10.1016/j.resconrec.2017.03.003 (Links to an external site.)

Background

This paper compares the efficiency of California Based traditional vegetable agriculture to hydroponics and aquaponics systems. Efficiency is defined by water usage, energy and nutrient input as it relates to crop yield. California is the leader in fruit and vegetable agriculture; therefore the rest of the United States is reliant on their system. However, California is also susceptible to severe drought, which can lead to reduce yields. Additionally, California has very large watershed, which can cause runoff of fertilizers in ponds, lakes and other bodies of water. Therefore to mitigate the environmental footprint of agriculture production, the author’s suggests that future generations focus on urban agriculture. Aquaponics is a system that allows the production of vegetables and fish, while reducing the input of fertilizers, and using waste byproducts as the source of nutrients. The authors show that this system reduces the nutrient input, water usage and is more productive that traditional based vegetable production. Therefore the purpose of this paper is to compare and contrast the productivity of each system.

Experimental Design

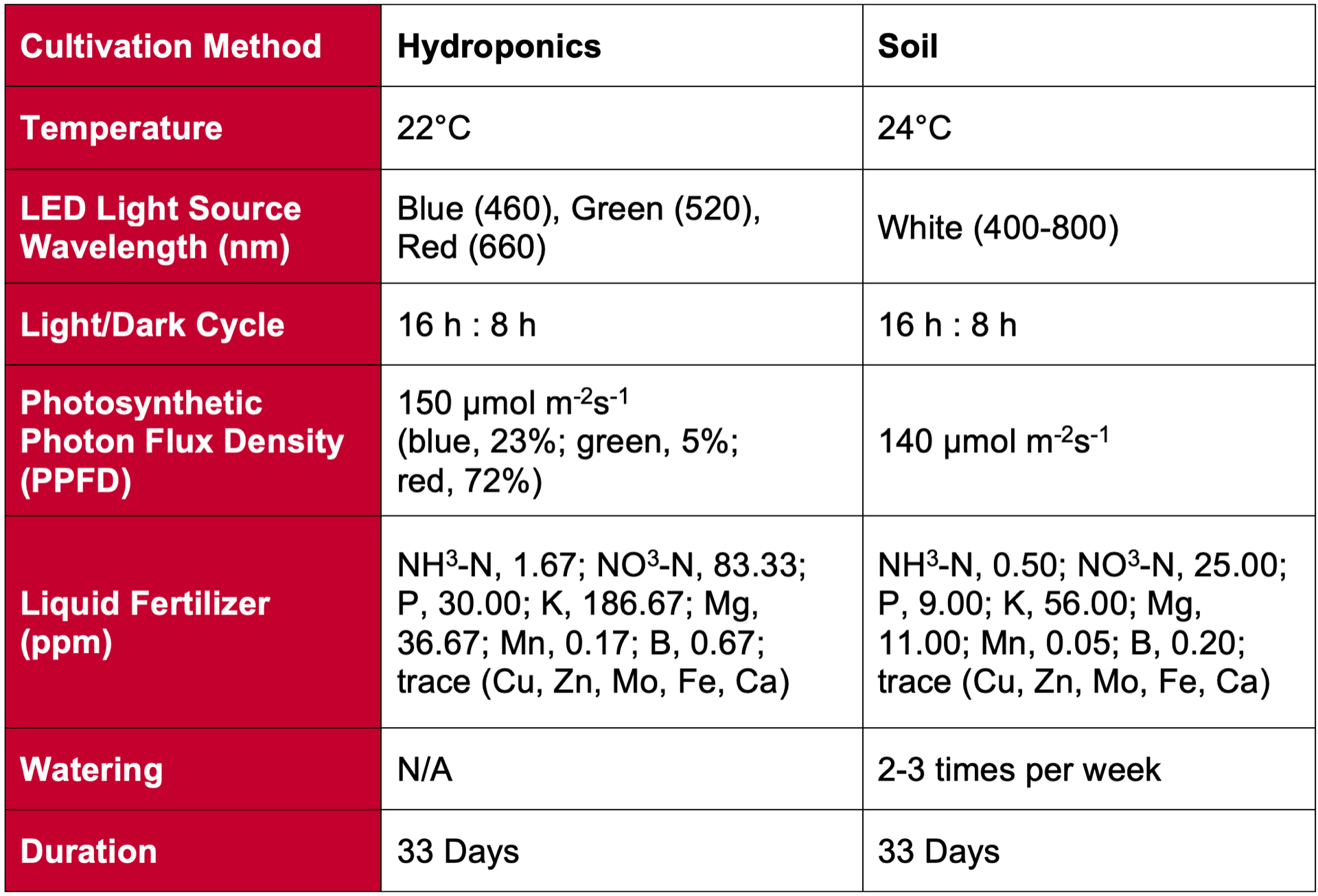

California vegetable data was derived from www.casestudies.ucdavis.edu. Data was taken for several crops including tomato, spinach, strawberries, peppers, and broccoli. The data displays yield, nutrient input, energy input for each crop. The data was normalized by dividing each component by yield per acre. For hydroponics, there was one grower who grew lettuce and leafy greens in shipping containers. The data was normalized for energy (lighting and cooling) and water usages over a year divided by yield per container. For aquaponics, there were three growers, one from Hawaii and two from University of Virgin Islands and Atlanta, GA. All growers used deep-water culture and grew leafy greens. The data was normalized for energy and water utilized over a year divided by the yearly productivity. Data from all three systems was then compared using statistical analysis.

Results

Areal Productivity

When comparing hydroponics and aquaponics there was no significant difference in the areal productivity. However, there was a significant difference between the ponic-systems and the California-based system. Ponic-systems were found to be 10 to 29 times more productive than the California-based system. In addition, areal productivity in hydroponics could be substantially improved increasing vertical production in closed environments.

Energy Usage

Hydroponics uses 30 times more energy (lighting, cooling) than the California-based system. There was no significant difference in energy usage between aquaponics and California-based system. However there were differences in energy usage between aquaponic growers, therefore it is would be wise to compare each aquaponic grower to the California-based system in the future.

Water Usage

California-system uses 66 and 8 times more water than hydroponics and aquaponics. There were differences in water usage between hydroponics and aquaponics, however the authors suggests that results maybe skewed due to the lack of data points.

Conclusion

Based on the authors study, it seems that ponic-systems are overall more efficient than California-based system. They believe that these systems should be integrated into urban cities. By integrating such systems, cities become less reliant on vegetable and fruit production from California. At the same time it reduces the negative environmental footprint. Nevertheless, the biggest challenge will be to address the socio-economic challenges in integrating the system into urban environments.