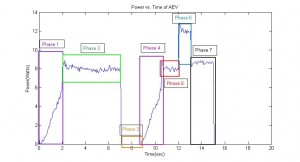

During this lab the team learned that it should use gravity as much as possible to minimize the energy consumption of the AEV as it navigates the course. The team will do this by only running the motors when the AEV is going up an incline or after the AEV makes a stop. The team also learned that the AEV needs to use the celerate function before the AEV brakes because this will allow the AEV to stop smoothly and lower the energy usage of the AEV. Before the team learned this they were using a motorSpeed in the opposite direction to negate the AEV’s momentum but with the celerate function the motorSpeed required to stop the AEV will decrease significantly. The AEV will also need a controlled decline as it goes down the hill to insure the safety of the passengers. Below shows the Power vs. Distance and Power vs. Time.