Preliminary R&D Lab

Exercise 1: Programming Basics

Progress Report Question 1: There was slight delay before the propellers started to move while accelerating the motors indicating a little resistance to move the motor at low speeds.

Arduino function calls table:

Note, variables are in bold for clarification and not required for the code.

Reference: LM_PreliminaryR&D_

Exercise 2: Reflectance Sensors

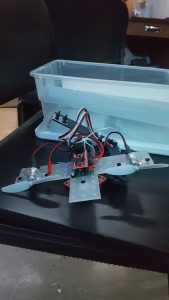

Arduino Sensory picture

The reflective sensors will be used to track distance this will be used to properly program the motors to run the correct speeds at the correct time. They work by both sensing the two conductive strips on the front side of the rear wheel and based on the circumference of the wheel to linear movement ratio, they can accurately track the distance traveled.

Progress report Question 2:

Success of the AEV may be limited by the commands used because it leads the distance to be hard to control. The brake command stops the motors over a certain time but the AEV will continue to move for a short period of time and cover more distance. The distance and time it travels after the motors stop will need to be precisely determined and will affect the code operating the AEV.

Exercise 3: Creative Design Thinking

Designs are displayed in the AEV Designs tab

Exercise 4: Data Analysis Tool

In this graph of Power v Distance, you can see the power slowly increase as the engines are accelerated to 25 % from 0 until it flattens out at around 0.05 meters and stays at 25% till 0.24 meters. Then the power drops and stays steady till 0.9 meters, representing the code. Then the power spikes around 0.95 meters, which represents the motors reversing. Then the motors run at 25% till 1.2 but the power is slightly higher than previously, due to the change in propeller direction. Then the motors brake and the line flattens out at 1.33 meters.

In this graph of Power v Time, you can see the power slowly increase as the engines are accelerated to 25 % from 0 until it flattens out at 3 seconds and stays at 25% till 4 seconds. Then the power drops and stays steady for 2 seconds, representing the code. Then the power spikes around 6 seconds, which represents the motors reversing. Then the motors run at 25% for 2 seconds but the power is slightly higher than previously, due to the change in propellor direction. Then the motors brake and the line flattens out at 0.

Code for Scenario 4:

//accelerate all engines from 0 to 25 for 3 seconds

celerate(4,0,25,3);

//set all motors to 25% for 1 second.

motorSpeed(4,25);

goFor(1);

//set all motors to 20% for 2 seconds.

motorSpeed(4,20);

goFor(2);

//reverse all motors

reverse(4);

//set all motors to 25% for 2 seconds.

motorSpeed(4,25);

goFor(2);

//brake all motors.

brake(4);

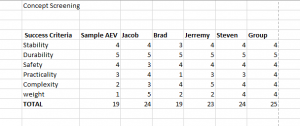

Exercise 5: Concept Screening and Scoring

Concept Screening:

Concept Scoring:

The categories were scored on a 0-5 score system where 5 is a high score and a 1 is a low score.

The pros and cons of the designs are located in the AEV designs tab.

We have decided to continue with the Team design (AEV-117) and Jacob’s base design for future testing and advanced research.

Advanced R&D Research

For advanced R&D research, tests were conducted on propellor and motor configuration to better propel our AEV faster and more efficiently. Mainly the test consisted of testing different motor and propeller configuration using one base code to see how our AEV performed. We collected data in of time to complete the code and the amount of energy used over that time. The results are as followed.

Advanced R&D – Propellor Configuration

The propellor Configuration Advanced R&D tested the different configuration of the propellers on the AEV motors. Different configuration tested the orientation of the propellers (pushing and pulling) and propellor size.

Configuration 1: Two propellers Pulling the AEV (Blue)

Both Propellers were both pulling the AEV. Both Propellers were the large, 3 1/4in Diameter. We found that this configuration performed the best out of all the configurations. With both larger propellers pulling in the same direction.

Configuration 2: Two Small Propellers pulling AEV. (Red), (yellow)

This configuration is the small (2 1/2 in diameter) propellers pulling in the same direction. This configuration barely even made the AEV, it required a little touch from someone to make it break the coefficient of static friction. We concluded this configuration and the small propellers were useless in general.

Configuration 3: Two large propellers, one pulling, on pushing. (Purple)

This configuration consisted both the two large propellers but one was pulling the AEV and one pushing the AEV. This performed better than the two small propellers but didn’t perform as well as when the propellers were working in the same direction. We also had to switch the polarity of one of the motors for this test and it resulted in the props spinning in different direction.

Graphs:

Takaways: It was concluded that configuration 1 was the best configuration to best propel the AEV with the least energy consumption.

Advanced R&D – Motor Configuration

The Motor Configuration Advanced R&D consisted of four different configurations of the motors and data analysis for all four designs. Overall all of these designs were less efficient at powering the AEV in both directions than having both motors facing forward.

Configuration 1 – Base

- Two propellers on the AEV plane pointing in the same direction

- This was our base configuration and performed the best out of all the other configurations

- Blue Data

Configuration 2

- Props at upward and downward angles

- This configuration didn’t perform the best but allows for the potential of helping the AEV climb the upward part of the track.

- Purple Data

Configuration 3

- both props angled downwards

- This configuration took a lot of time and energy to complete the course.

- Yellow Data

Configuration 4

- One prop forward one backwards

- This configuration didn’t make the AEV move at all

- No data could be recorded

Configuration 5

- props angled outwards off the sides

- This configuration used a little more energy than the base version but not a drastic amount. Also took a little more time.

- Red Data

Takeaways: We have found that our base configuration performed the best out of all the other configurations we tested. It propelled out AEV through the test code in the least amount of time and with the least energy.

Graphs

Moving Forward

- Collaborate with other groups to learn about other features of the AEV

- Implement large propellers and straight motor configuration

- Print the AEV body and assemble the AEV so further testing can be done