For the final performance test, the AEV performed all maneuvers required of it for the second performance test, but after linking to the caboose and reversing its motors to exit the loading dock, it had to travel up a slope to the gate, stop there for seven seconds, then pass through and coast down a slope to the starting dock. The code used was a further developed version of the low motor speed code variant developed for performance test two. The exact positions and motor speed used in the final version of the code were altered from those used in earlier tests as a result of the continually shifting battery power available.

Code used for the final performance test:

motorSpeed(4,27); //run both motors at 27% power

goToAbsolutePosition(238); //continue until AEV reaches 238 marks

brake(4); //stop both motors

goToAbsolutePosition(253); //coast until AEV reaches 253 marks

reverse(4); //reverse both motors

motorSpeed(4,25); //run both motors at 25% power for 2 seconds (air braking)

goFor(2);

brake(4); //stop both motors

goFor(7); //remain stopped for 7 seconds

reverse(4); //reverse both motors

motorSpeed(4,34); //run both motors at 34% power for 2 seconds (exit gate)

goFor(2);

brake(4); //stop both motors

goToAbsolutePosition(565); //coast until AEV reaches 565 marks

reverse(4); //reverse both motors

motorSpeed(4,25); //run both motors at 25% power for 1 second

goFor(1);

brake(4); //stop both motors

goFor(10); //coast for ~4 seconds, remain stopped for ~6 seconds

motorSpeed(4,55); //run both motors at 55% power

goToAbsolutePosition(450); //continue until AEV reaches 450 marks

brake(4); //stop both motors

goToAbsolutePosition(428); //coast until AEV reaches 428 marks

reverse(4); //reverse both motors

motorSpeed(4,41); //run both both motors at 41% power for 2 seconds

goFor(2);

brake(4); //stop both motors

goFor(8); //coast for 8 seconds

reverse(4); //reverse both motors

motorSpeed(4,55); //run both motors at 55% power for 3 seconds

goFor(3);

brake(4); //stop both motors

goToAbsolutePosition(64); //coast until AEV reaches 64 marks

reverse(4); //reverse both motors

motorSpeed(4,39); //run both motors at 39% power for 2 seconds

goFor(2);

brake(4); //stop both motors

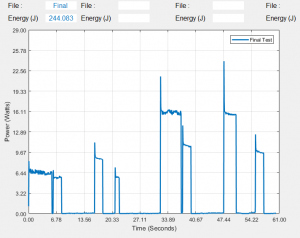

The test was successful with the exception of the AEV’s performance at the loading dock, where its front wheel rolled slightly out of the acceptable range before stopping. It was speculated that the air braking used at this point was not powerful enough, most probably as the result of decreased battery voltage because the tested run was the third run conducted with that same battery. Only one run was completed, due to time constraints. This run used 244.083 Joules of energy and lasted 57.07 seconds. The data from the final performance test is shown below.

The data collected from the final performance test was used to calculate the total cost of the AEV system. The costs associated with power and time use were calculated based on the data above, and added to their associated constant rates and the cost of the AEV itself. The breakdown of costs and the total cost is shown below.

Despite efforts do decrease energy expenditures by coasting on all downward sloped sections of track, the total cost of $623,069.47 exceeded the $500,000 budget by $123,069.47.