Available Equipment

Prof. Yang’s group specializes primarily in thin film growth of metallic and complex oxide materials. As such, we house a total of five deposition systems: the “main”, “auxiliary”, “oxide”, “L1”, and “L2” chambers. Our lab also houses several other pieces of equipment including: a vibrating sample magnetometer, three furnaces for materials synthesis, a planetary ball mill, and an optical table for a planned magneto-optical Kerr effect system.

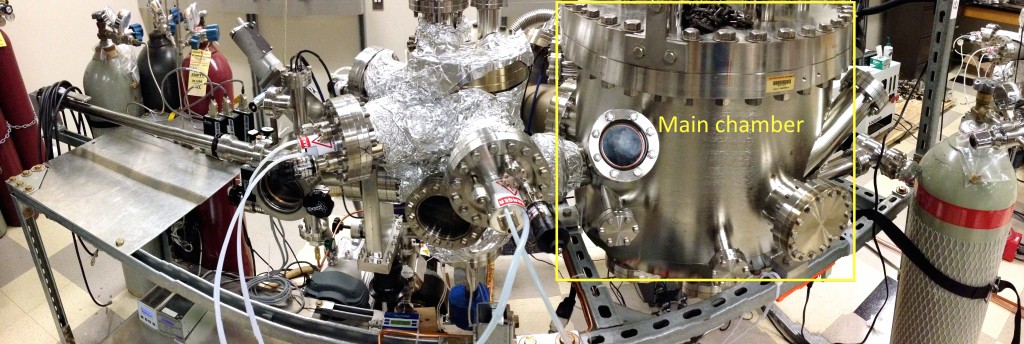

“Main” chamber

The “main” chamber was the original and first sputtering system in the Yang group. It is primarily used for metallic layers and heterostructures, as well as capping layers. The chamber has the capability for eight (8) available sources in an on-axis sputtering geometry mode and is operated via an automated LabVIEW stepper motor control program.

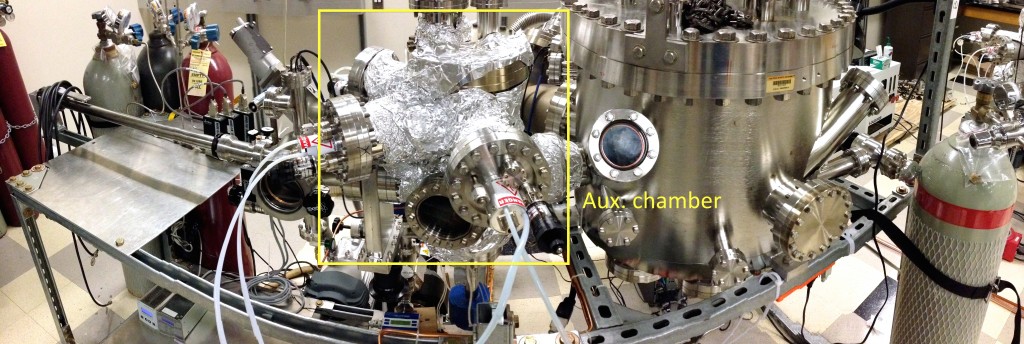

“Auxiliary” chamber

The “auxiliary” chamber was an add-on to the original “main” chamber and was used in our pioneer work of off-axis sputtering, primarily of complex oxide materials. The “auxiliary” chamber has the capability for four (4) available sources in an off-axis sputtering geometry mode and is manually operated.

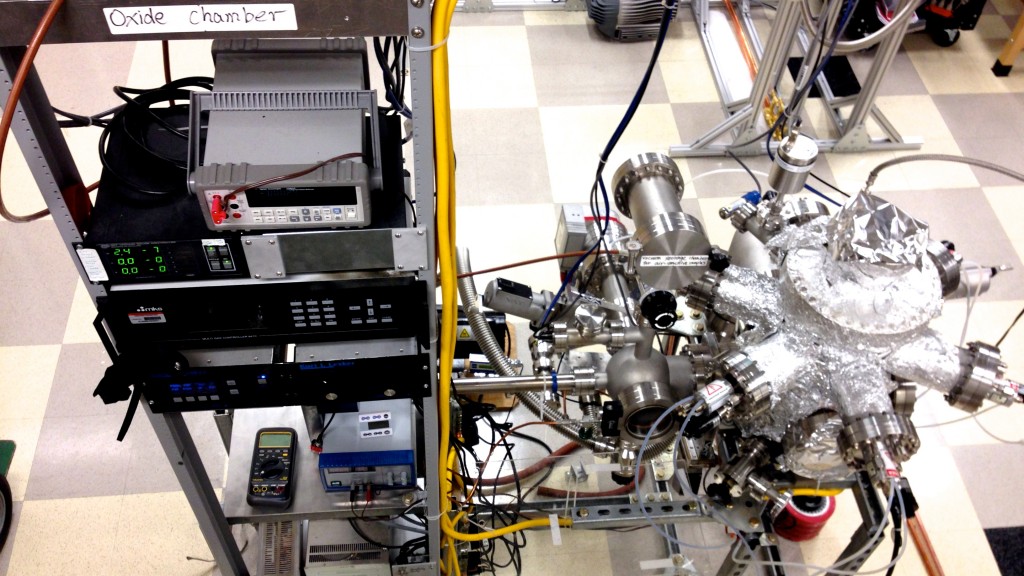

“Oxide” chamber

The “oxide” chamber was the group’s first system built and dedicated for off-axis sputtering, primarily of perovskite-like complex oxide materials. The “oxide” chamber has the capability for six (6) available sources in an off-axis sputtering geometry mode and is manually operated. As the big brother of the “auxiliary” chamber, the “oxide” chamber provides additional geometric flexibility for off-axis growth and allows for time-consuming dedicated oxide growths that do not interfere with metallic heterostructure growths of the “main” chamber.

“L1” off-axis sputtering chamber

The “L1” chamber is part one of the “L” chamber currently under development in the Yang group. It will be used in conjunction with the “L2” chamber in order to grow heterostructures of topological insulator films and complex magnetic materials. The “L1” off-axis sputtering chamber has the capability for four (4) available sources in an off-axis sputtering geometry mode and each source is mounted on a translation stage for added isolation of unused sources. The “L1” chamber will have RHEED capabilities for in-situ crystal growth monitoring to enable the highest quality growths possible.

“L2” molecular beam epitaxy chamber

The “L2” chamber is part two of the “L” chamber currently under development in the Yang group. It will be used primarily for the growth of bismuth-based topological insulator films. The “L2” chamber will be used for molecular beam epitaxy, a technique (relatively new to the group) which will enable further flexibility in heterostructure design and materials studies.

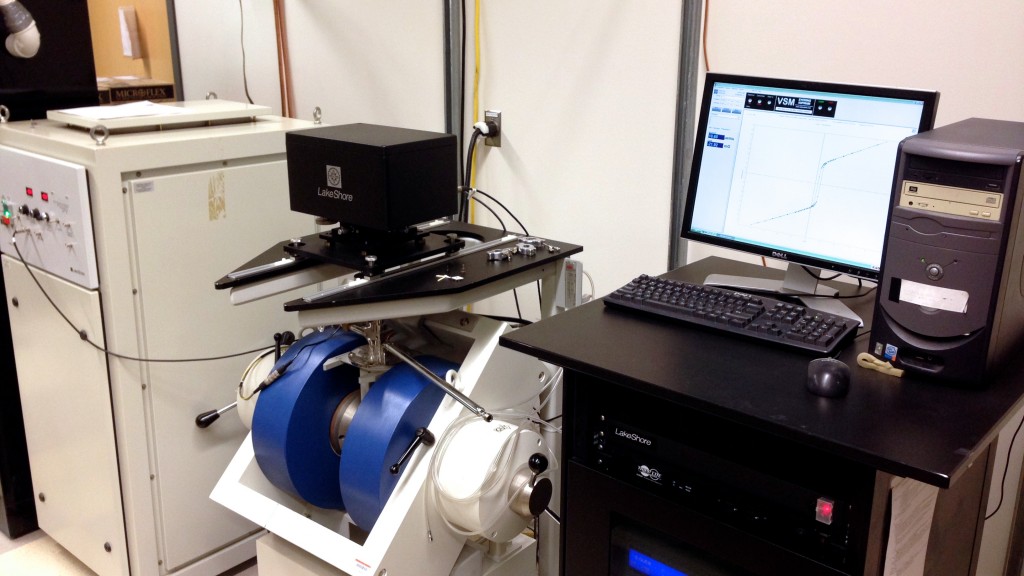

Vibrating sample magnetometer (VSM)

The VSM is our primary magnetometer capable of applying magnetic fields up to 1.6 T and controlling temperature from 5 K to 800 K (under two different cryostat modes). Custom measurements can be programmed for field sweeps or temperature sweeps. The VSM uses a vibrating sample head that can be rotated around 360 degrees.