The Nuclear Disaster at Three Mile Island

by Chien Liu

Figure 1. This 1979 photo of Three Mile Island shows steam rising from the unit that was damaged by a near meltdown two weeks later.

Source: Vrabel, 2014 <http:// www.ydr.com/remember/ci_8744078>

Overview

The 1979 accident at the Three Mile Island (TMI) nuclear power plant in Pennsylvania, as a turning point, opened up the nuclear industry to broad government and public scrutiny. The partial meltdown at Three Mile Island Unit 2 is considered to be the most serious nuclear accident in U.S. history but in fact it resulted in only small radioactive releases.

After this accident, it started to raise people’s awareness of Nuclear Safety Culture. Nuclear Safe Culture, defined by the U.S. Nuclear Regulatory Commission (2104) established in 1975, is the core values and behaviors resulting from a collective commitment by leaders and individuals to emphasize safety over competing goals to ensure protection of people and the environment in nuke industry.

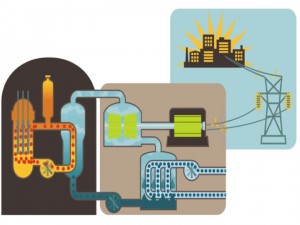

Figure 2. Nuclear Safety Culture Process

Source: Slider,2012 <http://www.safetymattersblog.com/2012/05/nei-safety-culture-initiative-good.html>

A combination of component failures, personnel errors, regulatory laxities and design deficiencies caused the Three Mile Island accident, which permanently changed both the nuclear industry and the NRC. Public fear and distrust increased. In order to appease public fear and anxiety, government’s and NRC’s regulations and oversight became broader and more robust, and management of the plants was scrutinized more carefully in the following years.

However, Electric Deregulation in the early 1990s had a great impact on Nuclear Safety Culture. Compared to safety, companies now put higher value on the economic costs, which has made this safety culture erode.

About the Accident

The accident began around 4 a.m. on March 28, 1979, in the secondary, non-nuclear section of the plant. A mechanical failure prevented the main feedwater pumps from sending water to the steam generators that remove heat from the reactor core. This caused the plant’s turbine-generator and then the reactor itself to automatically shut down. (NRC, 2014)

Immediately, the pressure in the primary system began to increase. In order to control pressure, the pilot-operated relief valve opened but it became stuck open afterward. As a result, coolant was pouring out through this stuck-open valve. As too much coolant escaped, the temperature in the reactor increased rapidly and thus reactor coolant pumps pushed extra water into the reactor but ran dry immediately and started to shake violently. Then, pressure began building. As the reactor got hotter and hotter, the fuel rods began to melt. (Parenti, 2011)

One technician then decided to turn on the pumps again refilled with water. Eventually, the reactor stopped shaking and pressure began to go down.

Figure 3~9. Animated Diagram of the Sequence of Events

Source: nrc.gov, 2103 <http://www.nrc.gov/reading-rm/doc-collections/fact-sheets/3mile-isle.html>

What Went Wrong?

Ugly facts began to emerge after the accident at Three Mile Island.

Component Failure: The pilot-operated relief valve should have closed when the pressure fell to proper levels, but it became stuck open in this case. (NRC, 2014)

Component Failure: The pilot-operated relief valve should have closed when the pressure fell to proper levels, but it became stuck open in this case. (NRC, 2014)

- Personale Error: Plant operators’ was misled by the instruments in the control room which indicated that the valve was closed and thus failed to correctly identify the valve was actually stuck open. (NRC, 2014)

- Regulatory Laxity: The closure of valves for routine maintenance was a violation of a key NRC rule. Once the secondary feedwater pumps stopped, three auxiliary pumps activated automatically but the valves had been closed for routine maintenace, the system was then unable to pump any extra water in this accident. (NewsThristy, 2011)

- Design Deficiency: It found out that reactor No. 2 had been rushed into service on the last day of 1978 since the utility company would have lost a $40 million federal tax break if waited one day more. (Parenti, 2011)

Figure 10. The top portion of Reactor 1

Sources: Rolls Press/Popperfoto, 1979

How this accident has affected current policy

This bitter lesson has branded on people’s mind.

The U.S. Nuclear Regulatory Commission made the first step. (NRC, 2014)

Figure 11. The logo of The U.S. Nuclear Regulatory Commission

Source: nrc.gov, n.d. <http://www.nrc.gov>

- It upgraded and strengthening of plant design and equipment requirements. This includes fire protection, piping systems, auxiliary feedwater systems, containment building isolation, reliability of pressure relief valves and electrical circuit breakers, and the ability of plants to shut down automatically.

- It hired 146 inspectors along with a stricter professional training program for them. With commission’s budget significantly increased between 1979 and 1981, it hired even more inspectors.

- It expanded NRC’s resident inspector program to have at least two inspectors live nearby and work exclusively at each plant in the U.S. to provide daily surveillance.

- It set up a stricter licensing process and more qualifications for utilities to build nuclear power plant

Figure 12. The logo of Institute of Nuclear Power Operations

Source: inop.info, n.d. <http://www.inpo.info/Index.html>

Within nine months of the accident, the industry also established Institute of Nuclear Power Operations (INPO), whose mission is to promote the highest levels of safety and reliability in the operation of nuclear power plants. Furthermore, INPO formed the National Academy for Nuclear Training, which reviews and accredits nuclear utilities’ training programs for all key positions at each plant. INPO is believed to have a profound impact on the way nuclear plants are managed and operated since the accident at TMI (Nuclear Energy Institute, 2014).

What’s more, President Carter signed stricter federal safety standards including mandatory emergency evacuation plans and harsher penalties for violations by utilities into laws.

Thanks to all these safety improvement policies, the nuclear industry turned out to be better organized, transparent and professional in the following years.

What still needs to be done

Everything has two sides. One might benefit while the other might be harmed. For most citizens and governors, nothing is more important than people’s safety. However, everything has its price. To pay dearly for public safety, a huge amount of money was necessary to keep this safety regime persistent.

A 1995 study in the Journal of Applied Econometrics found that nuclear power plants became “substantially less profitable” after the post-TMI safety regime. In fact, “over 90% of the expected discounted profits from continued operation of existing nuclear power plants have been eliminated in the post- TMI period.”(Rust & Rothwell,1995) A few half-built plants, now forced to meet stricter safety standards, went broke. Building new ones became more expensive, and plans for 100 other plants were canceled because of costs.

The desperation to get out from under debts due to building nuclear plants drove the push for electric deregulation in the early 1990s. (Wilpert & Itoigawa, 2001)

- Reducing operating and maintenance (O&M) cost:

It might lessen the effectiveness of safety systems and impede operator effectiveness in preventing accidents.

- Deferring maintenance:

This push for low costs and high production supplanted safety might lead to the rapid degradation of safety culture

- Reducing training costs:

This action decreased performance in operator licensing and requalification programs that might take the risk of human error.

- Cutting staffs:

It not only cut the plant’s operators but also cut the NRC’s staffs by almost half and restricts its inspection and enforcement activities.

- Shortening refueling outages:

The industry is seeking to bring the average refueling outage down to 24 days. Although these reductions do not necessary result in increased risk, careless attempts to reduce refueling time could.

Figure 13. Deregulation can be deadly

Source: Carol & Simpson, 2011<http://www.cartoonmovement.com/cartoon/3540>

The eroded safety culture is a source of serious danger. After all, the accident always happens when you let your guard down. According to the report by UCS nuclear engineer David Lochbaum, he examined fourteen “near-misses” at US nuclear plants in 2010, finding “a variety of shortcomings, such as inadequate training, faulty maintenance, poor design and failure to investigate problems thoroughly.” (Clayton, 2011) This is the sign that tells us to tighten those loose screws immediate before it is too late.

We need our Nuclear Safety Culture back!!

Figure 13. We need more inspectors back!!

Source: NAYGN Webcast, 2013 <http://naygn.org/event/ho-ho-ho-pi-presentation-library-webcast/>

References

Backgrounder on the Three Mile Island Accident. (December 12, 2014) Nuclear Regulatory Commission (nrc.gov). Retrieved from http://www.nrc.gov/reading-rm/doc-collections/fact-sheets/3mile-isle.html

Clayton, M. (March 18, 2011) Nuclear power report: 14 ‘near misses’ at US plants due to ‘lax oversight’. The Christian Science Monitor (csmonitor.com). Retrieved from http:// www.csmonitor.com/USA/2011/0318/Nuclear-power-report-14-near-misses-at-US-plants-due-to-lax-oversight

Fact Sheets—Lessons From the 1979 Accident at Three Mile Island (October, 2014). Nuclear Energy Institute (nei.org). Retrieved from http://www.nei.org/master-document-folder/ backgrounders/fact-sheets/the-tmi-2-accident-its-impact-its-lessons

NewsThristy. (March 16, 2011) Nuclear Disasters: Chernobyl, Three Mile Island. CNN iReport. Retrieved from http://ireport.cnn.com/docs/DOC-573262

Parenti, C. (March 22, 2011) After Three Mile Island: The Rise and Fall of Nuclear Safety Culture. TheNation.com. Retrieved from http://www.thenation.com/article/after-three-mile-island-rise-and-fall-nuclear-safety-culture/

Rust, J & Rothwell, G (November 7, 2006). Optimal response to a shift in regulatory regime: The case of the US nuclear power industry. Journal of Applied Econometrics Supplement ,Volume 10, Issue Supplement S1. Retrieved from http:/ /onlinelibrary.wiley.com/ doi/10.1002/jae.3950100506/abstract

Safety Culture. (March 26, 2014) Nuclear Regulatory Commission (nrc.gov). Retrieved from http:// www.nrc.gov/ about-nrc/safety-culture.html

Wilpert, B. & Itoigawa, N. (September 13, 2001) Safety Culture in Nuclear Power Operations. CRC Press. Retrieved from https://books.google.com/books?id=H-BQRictQAMC&pg=PA104&lpg=PA104&dq=nuclear+Utility+Deregulation+Cut+the+NRC’s+staff&source=bl&ots=dYc2VJ0sgm&sig=AZzCcTd5SSJRmSAM0ZRlZzEOqSQ&hl=en&sa=X&ved=0CEcQ6AEwBmoVChMIo62D7dL6xgIVB6OICh3fQA61#v=onepage&q=nuclear%20Utility%20Deregulation%20Cut%20the%20NRC’s%20staff&f=false

Your photo description is incorrect. Cooling towers emit water vapor to the atmosphere. It is quite certainly not steam.

the most common form of water vapor is….STEAM.