The Purpose for this lab is twofold, to generate and test a way for gathering the information collected by the AEV and to better understand how the AEV functions on the test runs. In order to complete this lab, both parts were tacked separately, with some working on the AEV and its Arduino code and some working on how to interpret and graph the data collected with MATLAB code. This lab took place over multiple days, and the not all of the data could be collected together, as the EXCEL spreadsheets given by the AEV were not collected for the second part of the lab, but the code for the AEV to run in the second part of the lab.

Below are the results for the half-track runs.

Figure 1. Watts vs. Distance for flat run 1

Figure 2. Diagram of the watts vs. time for flat run 1

Table 1. Phase Breakdown for flat run 1

The flat track run 1 went well but by the data generated for half-track 2 was lost and could not be included in the lab report. As such, conclusions will be drawn from the first half track run alone. The flat track that was tested was coded simply but was enlightening when it came to a couple of concepts. Unsurprisingly, the part of the run that was the required the least amount of energy was the one that had the AEV not running it’s propellers, but what was surprising was the fact that the energy that it consumed was not zero. The other aspect that was interesting to note was how the third phase of the test took less energy than the first aspect. This part was shorter, however when looking at the Watts vs. Time graph it is apparent that even as a whole the entire thing required less power to operate even with the motors set to the same speed. This will make it so that the team will do two things in the future. When it is possible to have the motors not running, have them turned off, but have the AEV at a standstill for as little as possible.

Below are the results from the half-track runs.

Figure 3. Compressed plot of the half-track data

Figure 4. Plot of the power versus time

Table 2. Phase breakdown for the half-track run

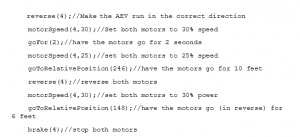

For the half-track run, there was not much information that was used from the flat runs that was carried into the new run. The group members that worked on the flat track were not the same that worked on the half-track run, so there was little crossover. The interesting thing to note from this run, is how power is saved when the motors stop running yet the AEV keeps moving.

The issues that were encountered during the testing phase were slight for the flat track runs, but for the half-track runs the main issues were getting within the correct test parameters. The code had to be tweaked, then run, then tweaked again to get the test to complete correctly which took a fair amount of time to complete.