Lab 1: Arduino Coding Test (P R&D)

The following code was used to test the Arduino program and to get used to coding commands for our AEV (P R&D Page 11):

| Lab 1 code: | //Accelerate Motor 1 from start to 15% power in 2.5 seconds celerate(1,0,15,2.5);//Run motor 1 at a constant speed (15% power) for 1 second goFor(1);//Brake motor 1 brake(1);//Accelerate motor two from start to 27% power in 4 seconds. celerate(2,0,27,4);//Run motor two at a constant speed (27% power) for 2.7 seconds. goFor(2.7);//Decelerate motor two to 15% power in 1 second celerate(2,27,15,1);//Brake 2 brake(2);//Reverse 2 reverse(2); brake(2);//Accelerate all motors from start to 31% power in 2 seconds celerate(4,0,31,2);//Run all motors at a constant speed of 35% power for 1 second celerate(4,31,35,1); goFor(1);//Brake motor two but keep motor one running at a constant speed (35% power) for 3 seconds. motorSpeed(1,35); brake(2); goFor(3);//Brake all motors for 1 second. brake(4); goFor(1);//Reverse the direction of motor one. reverse(1);//Accelerate motor one from start to 19% power over 2 seconds. Run motor two at 35% power while simultaneously running motor one at 19% power for 2 seconds. celerate(1,0,19,2);celerate(2,0,35,2);//Run both motors at a constant speed (19% power) for 2 seconds. motorSpeed(2,19); motorSpeed(1,19); goFor(2);//Decelerate both motors to 0% power in 3 seconds. celerate(1,19,0,3);celerate(2,19,0,3);//Brake all motors brake(4); |

Our code ran successfully according to scenario one.

Lab 2: Reflectance Sensors (P R&D)

| Lab 3 code: | celerate(4,0,25,3); //Runs all motors at 25% power for 3 seconds

goFor(1); //Runs all motors at a constant speed for 1 second motorSpeed(4,20); //Increases the motor’s speeds to 20% power reverse(4); //Makes the vehicle go in the opposite direction motorSpeed(4,25); //Increases the motor’s speeds to 25% power brake(4); //Stops all motors |

Lab 3 Data

Lab 4 AEV designs (P R&D)

Possible Design-1 |

I chose this design to allow the AEV to be able to move forward much more efficiently. The sleek outer shell will allow the AEV to be much more aerodynamic, lessening the impact of wind resistance. This will allow the AEV to require much less power when moving and can achieve much faster rates at a quicker pace. This fixes the problem of the AEV taken too much time to start moving once the motors begin to rotate. |

Possible Design-2 |

This design was chosen because it enables the AEV to travel forwards and backwards at the same speed and acceleration because the two motors are facing opposite directions from each other. This problem was evident during the first test when one direction seemed harder for the motors to move the AEV. This design also evenly distributes the weight of the vehicle by being symmetrical on either side of the track. |

Possible Design-3 |

I created this design for maximum carrying capacity. The two layers on the AEV would allow for more people to be carried, while still having a spherical front for aerodynamic purposes. The one downfall to this design would be the increased weight of adding another whole floor to the vehicle. |

Possible Design-4 |

This is a combined design of design 1 and 2. It includes the aerodynamic plastic shell from design 1 to increase energy efficiency as well as the low material and symmetry from Design 2. |

Lab 05 Concept Screening/Scoring (P R&D)

Concept Screening

| Success Criteria | Reference | Design 1 | Design 2 | Design 3 | Design 4 |

| Price of Parts | 0 | 0 | + | – | + |

| Aerodynamics | 0 | + | 0 | 0 | + |

| Stability | 0 | + | + | 0 | + |

| Weight | 0 | – | + | 0 | + |

| Efficiency | 0 | 0 | 0 | 0 | + |

| Sum + | 0 | 2 | 3 | 0 | 5 |

| Sum 0 | 0 | 2 | 2 | 5 | 0 |

| Sum – | 0 | – | 0 | 1 | 0 |

| Net Score | 0 | 1 | 3 | -1 | 5 |

| Continue? | Combine | No | Yes | No | Yes |

Concept Scoring

| Reference | Design 2 | Design 4 | |||||

| Success Criteria | Weight | Rating | Weighted Score | Rating | Weighted Score | Rating | Weighted Score |

| Price of Parts | 25% | 3 | 0.75 | 4 | 1 | 4 | 1 |

| Aerodynamics | 20% | 3 | 0.6 | 2 | 0.4 | 3 | 0.6 |

| Stability | 15% | 2 | 0.3 | 2 | 0.3 | 2 | 0.3 |

| Weight | 15% | 3 | 0.45 | 3 | 0.45 | 2 | 0.3 |

| Efficiency | 25% | 3 | 0.75 | 3 | 0.75 | 3 | 0.75 |

| Total Score | 2.85 | 2.9 | 2.95 | ||||

| Continue? | No | Develop | Develop | ||||

Criteria Descriptions

Price of Parts: We want our parts to be as be affordable, allowing for more budget leeway for other parts of the AEV

Aerodynamics: We want our AEV to allow the air to flow around, causing less air resistance, thus making the AEV more efficient

Stability: We want our AEV to have little to no chance of falling off of the track at ay given time

Weight: We want our AEV to be as lightweight as possible, making it easier for the motors to carry it further

Efficiency: We want our AEV to use as little energy as possible, while at the same time moving as far as it possibly can

Design Pros/Cons

Design 1:

Pros:

- Unlikely to fall off the track

- Shell allows for low air resistance

Cons:

- Very heavy, difficult for motors to move it

Design 2:

Pros:

- Parts used are cheap and reliable

- Unlikely to fall off the track

- Extremely lightweight

Cons:

- Opposite facing motors may not work as well as motors facing the same direction

Design 3

Pros:

- Circular front allows for a small amount of aerodynamics

Cons:

- Use of expensive custom parts

Design 4

Pros:

- Very cheap and reliable parts

- Curved, raised wings to allow for better airflow around the AEV

- Extremely unlikely to fall off the track

- Use of few parts lessens the weight of the AEV

- A smaller charge allows the AEV to go further than other designs

Cons:

- Intricate designs can be difficult to remake should the design be damaged

Lab 09 Reflectance Sensor Test (A R&D)

The purpose of this lab was to test the reflectance sensors and the reflectance tape of the wheel of the AEV to determine the needed parameters of the AEV in order to acquire the most accurate distance reading from the sensors. Several tests were done on different aspects of the sensors to test its accuracy, the first test being how the tightness of the wheel to the rack affected the accuracy of the AEV’s distance sensor. The next test determined how the quality of the reflectance tape affected the accuracy of the sensors. Based on this test, the most accurate readings are from a tight wheel and good quality tape. This can be determined because the tests had within 10% error, whereas a looser wheel or poorer quality tape had a greater percent error. Our AEV will not depend entirely on the accuracy of the location of the AEV, but will factor in the inaccuracy of the reflectance sensors.

Code Used:

motorSpeed(4,30); //Sets motor speed to 30%

goFor(3.5); //Runs motor for 3.5 seconds

brake(4); //Stops the motor

|

|

|

|

|

Lab 10 Voltage Test (A R&D)

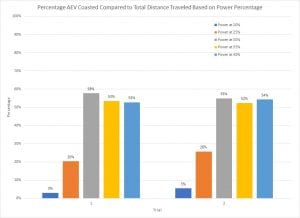

The purpose of this lab was to test how much the vehicle will coast at certain voltages. The total distance was measured and the distance coasted was determined by the number of marks the arduino recorded once the power went to 0. The data shows the greater the voltage the longer the vehicle will coast, however after 35% power, the distance coasted was about the same as the distance coasted at 40%. However, the actual distance coasted is inaccurate because the reflectance sensor test above proves that the ideal conditions still result in a 10% lab error. This AEV will coast to a stop to be more energy efficient, and it will be able to move the performance tests along faster, by knowing the distance the AEV is expected to travel at a certain distance for a certain period of time.

Code Used:

motorSpeed(4,X); //X is the speed of the motor, depends on trial (20, 25, 30, 35, or 40)

goFor(3);

Energy Reduction testing (Adv R&D)

The purpose of this lab is to change the code of the AEV so that less energy is used. The energy usage was measured using the Arduino data extraction tool and compared over two different tests. To save time, multiple trials were not run because the energy usage was planned to change so drastically that having two sets of generally the same energy would not be useful.

|

This trial focused on decreasing the voltage used after the incline and stopping before the gate with the caboose. After the original code in blue, the orange code shows how the voltage climbing the incline was decreased so that the energy used to flip the motor could be less and start at a later time. This tests proved that the energy was decreased because the peak of the orange is less than the peak of the blue. |

|

This trial focused on decreasing the voltage for stopping the momentum of the AEV after the decline with the caboose. The time that the motors turned off was stopped sooner than in the previous trial so that there would be less momentum at the end of the decline and the reverse of the motors could be used later and for less power. |

|

This trial focused on the end of the mission similar to the trial above. This trial was the least successful because the max amount of energy used was not as drastic of a change between the two trials. By reversing the motors earlier, the AEV’s momentum will be stopped and the reverse of the motors does not need to continue for as long as the motors reversed for in the trial before, represented by the color green. |