Progress Report 1

Backward looking summary:

Situation

This lab set out to accomplish several objectives; set up and upload the AEV software, program said software according to specific guidelines, and have group members become familiar with the software/hardware used throughout the AEV project. The group first set up the retrieved and set up the required equipment (2 motors, Li-Po battery, and the Arduino). This caused a bit of an obstacle in the first lab session because the AEV kit given to team members lacked the 2 necessary motors, however this problem was fixed upon some aid from the TAs. Once, the equipment was set up, the “Sketchbook” zip folder was downloaded and prepped for the experiment. Following this, the test scenario was carried out according the the desired specifications. The reflective sensors test is performed prior to all the labs in order to test the functioning of the important part required to begin the lab..

Results & Analysis

Upon setting up the test program and coding the desired scenario the group realized how detailed one needed to be when transcribing/typing out the code. It took several attempts of trial and error to correctly upload and compile the code for the Arduino. This did delay the group’s progress however, it provided an opportunity to become more familiar with the skill of troubleshooting.

Another issue was discovered when the code had been uploaded but it appeared the Arduino was not carrying out the test after the “start” button had been pressed. Through some further troubleshooting it was discovered the Arduino’s reset button had been pressed each time instead of the actual start button. This code was then re-uploaded to the Arduino and the test carried out.

The test itself was rather quick and finished with relative ease. The team was surprised to find the ‘brake’ command did nothing to reverse the motors, but merely cut the power to them. This was noted for when the team will construct the AEV. The team initially believed the brake command would ensure a safe slow down for the AEV, but upon making this discovery we discussed how we could adjust our idea with the available Arduino commands.

The code written for scenario 1 has worked as much as expected without any errors. However there was some resistance experienced in the motors every time they began to run. A time span of approximately half a second is took by the motors to spin smoothly with their highest potential and with negligible resistance.

The break command used in programming for scenario 1 indirectly slows down the motor. but, what actually happens here is that, when the break command is used the power being supplied to the motor stops for a give span of time. This makes the motor move at a lower speed than required. Before using the break command the motor has some acceleration alreast build in which makes it run for at least a short distance.

Although there were different ideas from all the team members about the design for the AEV model, all these ideas are tested with the help of concept screening and scoring matrices. After a detailed analysis of the pros and cons of the models a team design is selected. Nathan’s concept map is selected to be the team’s ideal model. This is because of the intricate idea of making our vehicle aerodynamic with the added nose. Another reason why this is our team concept map is because of the simplification it would bring to our code. It would also take advantage of the use of brakes instead of relying on the AEV to stop on its own. The cost of all the parts used in the AEV design came up to a total of around 160 to 180 dollars. All the designs of the team members are displayed in the appendix.

After the concept screening matrix, Team C moved on to the concept scoring matrix. Here, each success criteria was given a weight of importance. A minimal amount of maintenance was given the highest weight since it will save, the already limited amount of, lab time, as well as, money. This will allow Team C to allocate time to working on improving the efficiency of the AEV. Safety was also given a high weight of importance since the cost of injury or equipment failure is not in the budget. Stability was given the third highest weight since a perfect center of balance will increase efficiency, which is the main goal of the AEV. Minimal blockage was given a 10% weight of importance since it will be an easy fix if the propellers are blocked. Durability was given a 10% weight of importance since a minimal amount of maintenance was given a large weight. A light amount of maintenance will account for a durable product. After completing the concept scoring matrix, Nathan’s design received the highest score.

Takeaway

- Focus on the center of balance of the AEV

- Make sure no equipment is blocking the propellers

- When assembling the AEV, make sure it is structurally sound in order to reduce the need for maintenance

- Use durable products for the nose of the AEV

- Work on using the Servo Motor to turn the AEV at the end of the course

- Became familiar with AEV pseudo-code

- Discovered new limitations of the Arduino (break command)

- Learned how to properly set up the battery, Arduino, and motor system

Forward Looking Summary

Situation:

Next lab four will be continued. Lab four involves using the design analysis tool and the team not able to upload the Arduino data into the design analysis tool so plots were not exported. This will be the first thing to be completed because this data is useful to evaluating AEV performance and the design analysis should be used in all future labs. The team will bring a set up AEV to class and then make sure the analysis tool app is installed. Then the EEProm File which has a file containing data recorded by the Arduino motor controller will be opened, and this data will be used to extract a power vs. time plot and a power vs. distance plot.

After lab four is completed, the team will move onto the advanced R&D portion of this lab. The advanced R&D includes weeks 5-7. The purpose of the next part of this project is to conduct research that will further improve the AEV, to experiment with prototypes, and to conduct more performance tests. The guided topics Team C will be covering are servo function, materials testing, and propeller configuration. The propeller configuration will be tested by running test runs on different propellers and analyzing the data and determining which propellers have more advantageous features such as being faster or more efficient. The purpose of this portion of the lab is to determine which propeller or propellers may be better to use. Testing materials will require a development of a method to compare different materials to come to a conclusion of which materials would create the best AEV. The servo testing part of the lab will require the team to understand how the servo motor works. The servo motor is an optional hardware piece that can rotate to a desired angle. The purpose of this part of the lab is to decide is the servo motor would be a helpful component to add to the AEV.

Upcoming Goals:

The most important goal right now is to complete lab four because the data analysis tool will also be used in future labs to analyze the performance of the AEV. The team aims to meet this goal within the first 20 minutes of week 5 because finishing lab four as fast as possible will leave more time for the team to continue on to the advanced R&D parts of the lab. The goals for weeks 5-7 include testing one of the three guided topics each week during lab and finishing the progress report questions the day the labs are completed. Also the team will complete the website deliverers on the days of the lab. Progress report questions and website deliverable questions will be completed in lab, but if the lab takes too long, the team will meet after lab to complete the questions and delivereables.

Upcoming schedule

| Task Start | Members present | Date | Due Date | Time Needed |

| Lab Week 5-finish lab 4 and start testing propellers | 2/8/18 | 2/8/16 | 1hr | |

| Multiple testing of AEV | 2/8/16 | 2/8/16 | 1hr | |

| Determining if coasting and power braking | 2/15/18 | 2/15/18 | 2hrs | |

| Verifying the AEV wheel count sensor | 2/22/18 | 2/22/18 | 2hrs | |

| R&D oral presentation | 2/24/18 | 2/28/18 | ||

| Website update 3 | 2/28/18 | 3/1/18 | ||

| Testing different motors | 3/1/18 | 3/1/18 | 2hrs | |

| Progress report 2 | 3/3/18 | 3/8/18 | ||

| Performance test | 3/8/18 | 3/8/18 | 2hrs | |

| Identifying other methods of propulsion for the AEV | 3/11/18 | 3/15/18 | ||

| Understanding the functions of servo motor | 3/22/18 | 3/22/18 | 2hrs | |

| Performance with solidworks | 3/29/18 | 3/29/18 | 2hrs | |

| Final performance testing | 4/12/18 | 4/12/18 | 2hrs |

References

- Densities of Solids. (n.d.). Retrieved April 18, 2018, from https://www.engineeringtoolbox.com/density-solids-d_1265.html

- Medium-density fibreboard. (2018, April 10). Retrieved April 18, 2018, from https://en.wikipedia.org/wiki/Medium-density_fibreboard

Appendix

Meeting 1

Date: 1/17/2018

Time: 4:00 pm

Members present: Marley Mclaughlin, Nathan Teeters, Sanila Reza, Shreya Byreddy

Location: Hitchcock hall

Topics discussed:

roles each person should be assigned in order to complete the webpage update and team

meeting minutes

Objective:

The main aim of today’s meeting was to complete analyzing the basic steps to be taken in

Upcoming

To do/action items:

Initializing the website and discussing about the approach towards Mission Concept Review

Decisions:

Marley would be setting up the company website and will add other members into with the help

of their name.#. Nathan is assigned the job of creating the cover page for our team(team C).

Shreya Byreddy is supposed to write the meeting notes for the first meeting. Shanila would be

working on creating the drop down menus and team members are going to help her. All these

decisions were to reduce the workload and to make all team members participate in the

process.

Reflections

We had all team members performing the tasks assigned to them

All of them have cooperated pretty well in setting up the website.

Meeting 2

Date: 1/24/2018

Time: 5:00 pm

Members present: Marley Mclaughlin, Nathan Teeters, Sanila Reza, Shreya Byreddy

Location: Thompson library

Topics discussed:

Work that needs to be contributed by each member of the team to do the reflective sensor test

Objective:

The main aim of today’s meeting was to pre plan the things that need to be done in lab and code the scenario and arrange the parts of reflective sensor beforehand in order to save time. Apart from that team members have decided to design one concept sketch on their own so as to analyze it in the next lab.

To do/action items:

Discussion about the upcoming lab 2 and splitting up the work so as to finish the lab in given amount of time

Decisions:

Marley and Nathan are supposed to work on arranging the reflective sensors and make sure that all parts are present..

Shreya Byreddy and Shanila would be responsible for designing the code for scenario 2 so as to test the reflective sensors

Reflections

Team members have performed all the tasks assigned to them accordingly.

All of them worked together to achieve tasks

Meeting 3

Date: 2/7/2018

Time: 3:30 pm

Members present: Marley Mclaughlin, Nathan Teeters, Sanila Reza, Shreya Byreddy

Location: Hitchcock hall

Topics discussed:

Steps that need to be followed to complete progress report 1 and things to brainstorm about concept screening and scoring.

Objective:

The main objective of today’s meeting is to split the tasks that are to be performed by different team members to make the work a lot easier. Also, to do analysis about the concept screening and scoring about the models of the design done in lab 3

To do/action items:

Complete the progress report 1 and finish the tables for concept screening and scoring related to all the designs including the team design.

Decisions:

Marley has to perform the job of working on tables and figures and the takeaways for each lab. Nathan would be working on situations and results and analysis for all the labs

Shreya Byreddy has to be looking over the appendix for all the labs and the comment the code for the scenarios in each lab as well as work on the would be responsible for fulfilling the working on the situation and the upcoming designing.

Reflections

There were some variation in the splitting of the work by eventually finished the progress report before the due date. Team members have cooperated to take the workload of others.

Scenario 1:

Arduino source code with comment statements:

celerate(1,0,15,2.5);// accelerates motor from 0 to 15 in 2.5 s

motorSpeed(1,15);

goFor(1);//Runs motor one at a constant speed (15% power) for 1 second

brake(1);// Brakes motor one.

celerate(2,0,27,4);//Accelerates motor two from start to 27% power in 4 seconds.

motorSpeed(2,27);

goFor(2.7);//Run motor two at a constant speed (27% power) for 2.7 seconds.

celerate(2,27,15,1);//Decelerate motor two to 15% power in 1 second

brake(2);//Brakes motor two.

reverse(2);//Reverses the direction of only motor 2.

celerate(4,0,31,2);//Accelerate all motors from start to 31% power in 2 seconds

motorSpeed(4,35);

goFor(1);// Runs all motors at a constant speed of 35% power for 1 second.

brake(2);

motorSpeed(1,35);

goFor(3);//Brakes motor two but keeps motor one running at a constant speed of 35%power for

3 seconds

brake(4);

goFor(1);//Brake all motors for 1 second.

reverse(1);//Reverses the direction of motor one.

celerate(1,0,19,2);//Accelerates motor one from start to 19% power over 2 seconds.

motorSpeed(2,35);

motorSpeed(1,19);

goFor(2);//Runs motor two at 35% power while simultaneously running motor one at 19%

power for 2 seconds.

motorSpeed(4,19);

goFor(2);//Runs both motors at a constant speed (19% power) for 2 seconds

celerate(4,19,0,3);//Decelerates both motors to 0% power in 3 seconds.

brake(4);// Brakes all motors.

Scenario 2:

Arduino source code with comment statements:

motorSpeed(4,25);

goFor(2);//Runs all motors at a constant speed of 25% power for 2 seconds.

motorSpeed(4,20);

goToAbsolutePosition(12);//Runs all motors at a constant speed of 20% and using the

goToAbsolutePosition function makes it to travel a total distance of 12 feet (from the starting

point). Wheels are rotated by hand until the wheel has completed the required distance and

the motors stop.

reverse(4);//Reverses all motors.

motorSpeed(4,30);

goFor(1.5);//Runs all motors at a constant speed of 30% power for 1.5 second.

brake(4);//Brakes all motors.

Straight track:

Arduino source code with comment statements:

celerate(4,0,25,3);//Accelerates all motors from start to 25% power over 3 seconds.

motorSpeed(4,25);

goFor(2);//Runs all motors at a constant speed of 25% power for 2 second.

reverse(4);//Reverses all motors

motorSpeed(4,25);

goFor(2);//Runs all motors at a constant speed of 25% power for 2 second.

brake(4);//Breaks all motors.

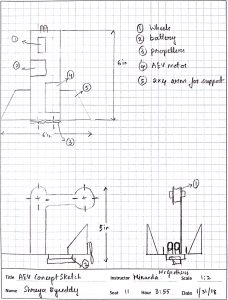

Below are the AEV design sketches done by all the individual team members during the

creative design part of the lab.

The main focus of my design is to minimize the amount of detailed coding needed for the Arduino. Accordingly, Nathan incorporated the servo motor to actually rotate the 2 motors 180 degrees so they could act as brakes. Subsequently, Nathan also added aerodynamic nose cones to both sides of the main body.

This AEV concept sketch is derived from the idea of equal weight distribution. The battery is placed on the opposite wing of the Arduino to distribute the weight. Two propellers are placed on the rear of the vehicle to allow for optimum power without interference from the other parts.

Team’s AEV design

The main focus of my design is to minimize the amount of detailed coding needed for the Arduino. Accordingly, I incorporated the servo motor to actually rotate the 2 motors 180 degrees so they could act as brakes. Subsequently, I also added aerodynamic nose cones to both sides of the main body.

The table below shows the concept screening worksheet put together by Team C.There are five success criteria. The first one is stability of the AEV. This was chosen since the AEV needs to be stable enough to coast along the track. If the product’s center of balance is off, then the AEV is not being an efficient as it could be. Minimal blockage was chosen to be a success criteria because if the propellers are blocked, this could create a hazard. Energy would also be wasted if the propellers are being interfered. Maintenance was chosen since money and time are limited. By striving for a scant amount of maintenance, this will save laboratory time and money. Durability was chosen to go coincide with limited maintenance. A durable product will need a less amount of maintenance throughout the design and testing process. These five criteria were constructed to evaluate the AEV concept sketches and to properly choose one to design and test. After completing the concept screening matrix, Nathan’s concept sketch prioritized the success criteria. His design will provide minimal blockage since there will be a nose for the main equipment. This will also provide the least amount of maintenance since the equipment has a shield. This is design is also safe compared to the others since it is stable and condensed into the nose. The other designs will not move on because of their lack of durability and increased amount of maintenance.

Concept Screening matrix

| Success Criteria | Shreya’s Design | Marley’s design | Shanila’s design | Nathan’s design | Baseline AEV |

| Stability | + | 0 | 0 | 0 | 0 |

| Minimal Blockage | 0 | + | – | + | 0 |

| Maintenance | 0 | 0 | – | + | 0 |

| Durability | – | – | + | 0 | 0 |

| Safety | – | 0 | – | + | 0 |

| Sums of +s | 1 | 1 | 1 | 2 | 0 |

| Sums of 0s | 2 | 3 | 1 | 3 | 5 |

| Sums of -s | -2 | 1 | 3 | 0 | 0 |

| Net Score | 1 | 0 | -2 | 3 | 0 |

| Continue? | No | No | No | Yes | combine |

After the concept screening matrix, Team C moved on to the concept scoring matrix. Here, each success criteria was given a weight of importance. A minimal amount of maintenance was given the highest weight since it will save, the already limited amount of, lab time, as well as, money. This will allow Team C to allocate time to working on improving the efficiency of the AEV. Safety was also given a high weight of importance since the cost of injury or equipment failure is not in the budget. Stability was given the third highest weight since a perfect center of balance will increase efficiency, which is the main goal of the AEV. Minimal blockage was given a 10% weight of importance since it will be an easy fix if the propellers are blocked. Durability was given a 10% weight of importance since a minimal amount of maintenance was given a large weight. A light amount of maintenance will account for a durable product. After completing the concept scoring matrix, Nathan’s design received the highest score.

Concept Scoring Matrix

| Success Criteria | Weight | Rating for Shreya | Weighted Score | Rating for Marley | Weighted Score | Rating for Shanila | Weighted Score | Rating for Nathan | Weighted Score | Rating for Reference | Weighted Score |

| Stability | 20% | 3 | 0.60 | 2 | 0.40 | 2 | 0.40 | 3 | 0.60 | 3 | 0.60 |

| Minimal Blockage | 10% | 2 | 0.20 | 4 | 0.40 | 1 | 0.10 | 4 | 0.40 | 3 | 0.30 |

| Maintenance | 30% | 1 | 0.30 | 2 | 0.60 | 1 | 0.30 | 3 | 0.90 | 3 | 0.90 |

| Durability | 10% | 2 | 0.20 | 1 | 0.10 | 4 | 0.40 | 3 | 0.30 | 3 | 0.30 |

| Safety | 30% | 2 | 0.6 | 3 | 0.90 | 1 | 0.30 | 2 | 0.60 | 3 | 0.90 |

| Total Score | 1.9 | 2.4 | 1.50 | 2.80 | 3.00 | ||||||

| Continue? | No | develop | No | Yes | No |

Takeaways

- Focus on the center of balance of the AEV

- Make sure no equipment is blocking the propellers

- When assembling the AEV, make sure it is structurally sound in order to reduce the need for maintenance

- Use durable products for the nose of the AEV

- Work on using the Servo Motor to turn the AEV at the end of the course