Performance Test 1

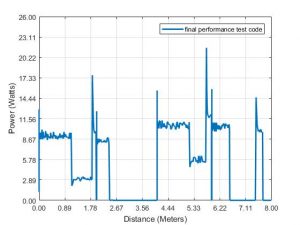

During the first performance test, the code designed by the team was used to test the designs. This code is presented in the appendix with comments that clearly explains tasks performed by the AEV for each command. From the graphs as seen in Figure A14 and Figure 3 obtained by the design analysis tool, it is observed that the vertical design using push configuration uses a maximum power of approximately 12.45 whereas the horizontal design with pull configuration uses a maximum power of 8.00. This, helped the team to decide the best design which is more energy efficient and aerodynamic. This eventually led to a successful run in performance test by implementing the improvements found by the team so far.

Figure 1: power vs. distance for the horizontal design

Figure 2: power vs. distance for the vertical design

Code used to test both horizontal and vertical design during performance test 1

motorSpeed(4,26.5);

//Runs all motors at a constant speed of 26.5% power

goToAbsolutePosition(123);

//sets all the motors to a constant power of 26.5% power until they reach a //position of 123 marks from its current position.

reverse(4);

//Reverses all motors

brake(4);

//brakes all the motors

goFor(9);

//breaks all the motors for 9 seconds

reverse(4);

//Reverses the polarity of all motors

motorSpeed(4,25);

goFor(3);////Runs all motors at a constant speed of 25% power for 3 seconds

brake(4);

//breaks all the motors

Performance Test 2

After the setup of the design from performance test 1 team C came up with two different code during the second performance test. Both the codes, that the team came up with, were analyzed and the second code that uses coast was expected to more energy efficient than the first code with power brake. As the second code uses a bake function for 12 seconds instead of an aggressive power break for getting attached to the caboose, the second code does not consume any power in this area. From further analysis of the figure 3 and figure 4 it is observed that the first code consumes a power of 31.11 whereas the second code does not use any energy and is a straight line at 0% power. Even though the power brake was perfect in its stopping position it consumed a lot of energy. This made team C to choose the second code and run multiple test to actually know where the AEV need to be stopped and allowed to coast.

Figure 3: power vs. time for the first code

Figure 4: power vs. time for the second code

First code that was used for performance test 2 (1st code)

reverse(4);//reverses all motors

motorSpeed(4,35);

goToAbsolutePosition(150);//runs all motors at a speed of 35% power until the AEV reaches a position of 150 marks from its starting point

reverse(4);//reverses all motors

motorSpeed(4,60);

goFor(0.5);//runs all motors at a speed of 60% power for 0.5 seconds

brake(4);

goFor(7);//breaks all motors for 7 seconds

reverse(4);//reverses all motors

motorSpeed(4,27);

goToRelativePosition(160);

reverse(4);//reverses all motors

motorSpeed(4,60);

goFor(0.5);//runs all motors at a speed of 60% power for 0.5 seconds

brake(7);

goFor(6);//breaks all motors for 6 seconds

motorSpeed(4,45);

goToRelativePosition(118);//runs all motors at a speed of 45% power until the AEV reaches a position of 118 marks from its current point

reverse(4);//reverses all motors

motorSpeed(4,60);

goFor(0.5);//runs all motors at a speed of 60% power for 0.5 seconds

brake(4);

goFor(6);//breaks all motors for 6 seconds

Second code developed by the team for more efficient AEV design (2nd code)

reverse(4);//reverses all motors

motorSpeed(4,35);

goToAbsolutePosition(147);//runs all motors at a speed of 35% power until the AEV reaches a position of 147 marks from its starting point

reverse(4);//reverses all motors

motorSpeed(4,60);

goFor(0.5);//runs all motors at a speed of 60% power for 0.5 seconds

brake(4);

goFor(7);//breaks all motors for 7 seconds

reverse(4);//reverses all motors

motorSpeed(4,37);

goToRelativePosition(53);//runs all motors at a speed of 37% power until the AEV reaches a position of 53 marks from its current point

brake(4);

goFor(15);//breaks all motors for 15 seconds

reverse(4);//reverses all motors

motorSpeed(4,45);

goToRelativePosition(118);/runs all motors at a speed of 45% power until the AEV reaches a position of 118 marks from its current point

reverse(4);//reverses all motors

motorSpeed(4,60);

goFor(0.5);//runs all motors at a speed of 60% power for 0.5 seconds

brake(4);

goFor(6);//breaks all motors for 6 seconds

Final Performance Test

The final performance test was implemented using the newest design and the second code along with some changes so that the AEV comes back thought the gate and stops at the same position of start. The team got rid of the side arms that support the propeller to reduce the cost of the design. Each team had three runs to finish the final performance test but team C was able to complete the entire run successfully in the first run. For the first run the AEV used 206.473J of energy which was below the class average being 219.2J. As the team did not use as many part for the horizontal design that were used for the vertical design. It reduced the cost of the final AEV to $159,080. Due to the usage of coasting the energy consumption was reduced but the time needed to go through the entire run increase to 55.68 which is 3.96 seconds more than the class average. Consequently, increased the time cost to be $172,500 which is more than the class average.

code used by team C during final performance test

reverse(4);//reverses all motors

motorSpeed(4,35);

goToAbsolutePosition(90);//runs all motors at a speed of 35% power until the AEV reaches a position of 90 marks from its starting point

motorSpeed(4,15);

goToRelativePosition(58);//runs all motors at a speed of 15% until the AEV reaches a position of 58 marks from its relative position

reverse(4);//reverses all motors

motorSpeed(4,38);

goFor(0.75);//runs all motors at a speed of 38% power for 0.75 seconds

brake(4);

goFor(7.5);//breaks all motors for 7.5 seconds

reverse(4);//reverses all motors

motorSpeed(4,32);

goToRelativePosition(34);//runs all motors at a speed of 32% until the AEV reaches a position of 34 marks from its relative position

brake(4);

goFor(12);//breaks all motors for 12 seconds

reverse(4); //reverses all motors

motorSpeed(4,41);

goToRelativePosition(90);//runs all motors at a speed of 41% until the AEV reaches a position of 90 marks from its relative position

motorSpeed(4,25);

goToRelativePosition(45);//runs all motors at a speed of 25% until the AEV reaches a position of 45 marks from its relative position

reverse(4);//reverses all motors

motorSpeed(4,45);

goFor(1);//runs all motors at a speed of 45% for 1 second

brake(4);

goFor(8);//breaks all motors for 8 seconds

reverse(4);//reverses all motors

motorSpeed(4,40);

goToRelativePosition(50);//runs all motors at a speed of 40% until the AEV reaches a position of 50 marks from its relative position

brake(4);

goFor(3.25);//breaks all motors for 3.25 seconds

reverse(4);//reverses all motors

motorSpeed(4,38);

goFor(0.75);//runs all motors at a speed of 38% for 0.75 second

brake(4);//breaks all motors at the end

Figure 5: power vs. time for the final performance test

Figure 6: power vs. distance for the final performance test

For any further improvements team C would be making much lighter 3D printed arts which could improve the energy to mass ratio. Moreover, team C would recommend to conduct more performance tests that focus on reducing the energy usage during turns on the monorail tracks. Additionally further labs could be improvised by testing the hardware equipment before the labs, to make sure that each team has a proper working hardware.

References

OSU College of Engineering, 1182, AEV Documents, MCR & Deliverables

OSU College of Engineering, 1182, Resources, Technical Communication Guide