Lab 1: Programming Basics

Tasks:

Team members have to corporate to setup the AEV software. Getting grip on automatic control system hardware components. Programming the basic function calls for giving the motor a running start. All the scenarios have to work perfect which includes uploading the programs on to the Arduino and testing them.

Scenario 1:

celerate(1,0,15,2.5);

// accelerates motor from 0 to 15 in 2.5 s

motorSpeed(1,15);

goFor(1);

//Runs motor one at a constant speed (15% power) for 1 second

brake(1);

// Brakes motor one.

celerate(2,0,27,4);

//Accelerates motor two from start to 27% power in 4 seconds.

motorSpeed(2,27);

goFor(2.7);

//Run motor two at a constant speed (27% power) for 2.7 seconds.

celerate(2,27,15,1);

//Decelerate motor two to 15% power in 1 second

brake(2);

//Brakes motor two.

reverse(2);

//Reverses the direction of only motor 2.

celerate(4,0,31,2);

//Accelerate all motors from start to 31% power in 2 seconds

motorSpeed(4,35);

goFor(1);

// Runs all motors at a constant speed of 35% power for 1 second.

brake(2);

motorSpeed(1,35);

goFor(3);

//Brakes motor two but keeps motor one running at a constant speed of 35%power for 3 seconds

brake(4);

goFor(1);

//Brake all motors for 1 second.

reverse(1);

//Reverses the direction of motor one.

celerate(1,0,19,2);

//Accelerates motor one from start to 19% power over 2 seconds.

motorSpeed(2,35);

motorSpeed(1,19);

goFor(2);

//Runs motor two at 35% power while simultaneously running motor one at 19% power for 2 seconds.

motorSpeed(4,19);

goFor(2);

//Runs both motors at a constant speed (19% power) for 2 seconds

celerate(4,19,0,3);

//Decelerates both motors to 0% power in 3 seconds.

brake(4);

// Brakes all motors.

Lab 2: Reflectance sensor

Tasks: The main goals for this lab is to test the proper functioning of the reflective sensors using the code for scenario 2. It is also tested by typing in the reflectanceSensorTest(); into 01_myCode. Apart from that this lab makes students familiar about the external sensors hardware components and programming function call for using reflective sensors along with AEV control. All these practices helps in knowing about the troubleshooting techniques.

Scenario 2:

motorSpeed(4,25);

goFor(2);

//Runs all motors at a constant speed of 25% power for 2 seconds.

motorSpeed(4,20);

goToAbsolutePosition(12);

//Runs all motors at a constant speed of 20% and using the goToAbsolutePosition function makes it to travel a total distance of 12 feet (from the starting point). Wheels are rotated by hand until the wheel has completed the required distance and the motors stop.

reverse(4);

//Reverses all motors.

motorSpeed(4,30);

goFor(1.5);

//Runs all motors at a constant speed of 30% power for 1.5 second.

brake(4);

//Brakes all motors.

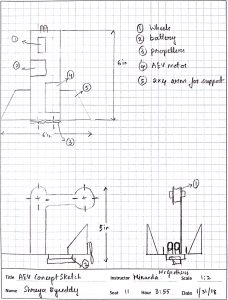

Lab 3: Creative Design Thinking

Tasks: A rough idea of where the parts have to be assembled in the AEV design model. Becoming familiar about the different parts present in the AEV kit. Trying to present the model in three different orthogonal projection helps gaining strength over orthographic drawings. All these aspects makes the team members familiarize with the different obstacles involved in creativity

After brainstorming about the possible opportunities involved in designing a safe model for AEV and came with this idea. This is effective in a variety of ways. It balances all the weight that is being placed on the model. All these aspects help the AEV to run in it’s normal condition without any distractions.

The main focus of my design is to minimize the amount of detailed coding needed for the Arduino. Accordingly, I incorporated the servo motor to actually rotate the 2 motors 180 degrees so they could act as brakes, instead of having to reverse the motors’ own rotors. Subsequently, I also added aerodynamic nose cones to both sides of the main body.

The focus of this design was to create an aerodynamic model. This would allow the a faster speed which would mean less energy would be required to move which would also save money.

This AEV concept sketch is derived from the idea of equal weight distribution. The battery is placed on the opposite wing of the Arduino to distribute the weight. Two propellers are placed on the rear of the vehicle to allow for optimum power without interference from the other parts.

Team concept sketch:

With enough analysis about the difficulties in each design, Nathan’s concept sketch for the AEV is selected as the team design. This is because of the intricate idea of making our vehicle aerodynamic with the added nose. Another reason why this is our team concept map is because of the simplification it would bring to our code. It would also take advantage of the use of brakes instead of relying on the AEV to stop on its own.

lab 4 Design Analysis Tool:

The goal in this lab is to get the graphs for power vs. time and power vs. distance when the arduino is uploaded with the code in the straight track. This also helps in analyzing how the commands effect the functioning of the Ardunio. It also helps in knowing the use of design analysis tool that provides an efficient and productive method to evaluate AEV performance

Straight track:

Arduino source code with comment statements:

celerate(4,0,25,3);//Accelerates all motors from start to 25% power over 3 seconds.

motorSpeed(4,25);

goFor(2);//Runs all motors at a constant speed of 25% power for 2 second.

reverse(4);//Reverses all motors

motorSpeed(4,25);

goFor(2);//Runs all motors at a constant speed of 25% power for 2 second.

brake(4);//Breaks all motors.

Lab 5 Concept screening and scoring:

The main goal of this part of the lab is to perform the tests on all the designs created above, using the sample model, and select the best two among all of them. These designs are them carried forward to the advanced design analysis. The following is the data collected during this process.

Concept Screening matrix

| Success Criteria | Shreya’s Design | Marley’s design | Shanila’s design | Nathan’s design | Baseline AEV |

| Stability | + | 0 | 0 | 0 | 0 |

| Minimal Blockage | 0 | + | – | + | 0 |

| Maintenance | 0 | 0 | – | + | 0 |

| Durability | – | – | + | 0 | 0 |

| Safety | – | 0 | – | + | 0 |

| Sums of +s | 1 | 1 | 1 | 2 | 0 |

| Sums of 0s | 2 | 3 | 1 | 3 | 5 |

| Sums of -s | -2 | 1 | 3 | 0 | 0 |

| Net Score | 1 | 0 | -2 | 3 | 0 |

| Continue? | No | No | No | Yes | combine |

Concept Scoring Matrix

| Success Criteria | Weight | Rating for Shreya | Weighted Score | Rating for Marley | Weighted Score | Rating for Shanila | Weighted Score | Rating for Nathan | Weighted Score | Rating for Reference | Weighted Score |

| Stability | 20% | 3 | 0.60 | 2 | 0.40 | 2 | 0.40 | 3 | 0.60 | 3 | 0.60 |

| Minimal Blockage | 10% | 2 | 0.20 | 4 | 0.40 | 1 | 0.10 | 4 | 0.40 | 3 | 0.30 |

| Maintenance | 30% | 1 | 0.30 | 2 | 0.60 | 1 | 0.30 | 3 | 0.90 | 3 | 0.90 |

| Durability | 10% | 2 | 0.20 | 1 | 0.10 | 4 | 0.40 | 3 | 0.30 | 3 | 0.30 |

| Safety | 30% | 2 | 0.6 | 3 | 0.90 | 1 | 0.30 | 2 | 0.60 | 3 | 0.90 |

| Total Score | 1.9 | 2.4 | 1.50 | 2.80 | 3.00 | ||||||

| Continue? | No | develop | No | Yes | No |