Table D was tasked with designing, creating, and testing a speedy, energy efficient AEV. They will be compared to the other tables, to see which team can complete the objective of delivering cargo from one side of the track to the other in the most efficient manor. The team not only has to construct the AEV itself, but must also design code that will help get the AEV to the cargo and back again. The team must also consider the gate that is placed in between the cargo and the starting position. As such, time and energy consumption is a major consideration that must be considered when designing the AEV as well as the code for running it. It is up to Table D, to deliver on what they were tasked on as well as create a reliable AEV for the Rebel Alliance.

Posts

The Team

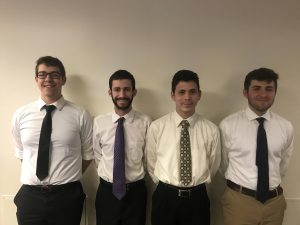

From Left to Right: Joe Sudar, Blake Harriman, Kyle Pellikan, Kyle Kottyan

Joe (jcs0902@gmail.com): My name is Joe Sudar, and I am a first year Chemical Engineering Pre-Major student at The Ohio State University. I am a first year STEM scholars student, and I am currently performing research under Dr. Marcos Sotomayor. Within the Fundamentals of Engineering AEV Design Project I have worked as the head designer, creating and altering the design, while also modeling in Solid Works.

Blake (BlakeAndrewHarriman73@gmail.com): My name is Blake Harriman and I am a first year computer science and engineering major at The Ohio State University. Within the Fundamentals of Engineering AEV design project I am responsible for writing code for the teams vehicle to have it complete the task of traveling to and bringing back cargo in a time and energy efficient way.

Kyle P (kylepellikan@gmail.com): I am Kyle Pellikan, and I am a first year Pre-Computer Science and Engineering Major at The Ohio State University. For the AEV project, my job was to keep track of the team’s schedule, as well as make sure the Project Portfolio was up to date every week.

Kyle K (kylelkottyan@gmail.com): My name is Kyle Kottyan and I am currently a first-year pre-Computer Science & Engineering major at The Ohio State University. The role I undertook for the duration of the AEV project was the team leader and organizer, while also aiding with data collection and processing and software creation.